When it comes to woodworking, the choice of fasteners is just as crucial as the selection of the wood itself. One of the most reliable options available today is stainless steel wood screws, known for their durability and resistance to corrosion. In our comprehensive guide for 2025, we will elaborate on the key considerations for choosing the best stainless steel wood screws for your projects. Understanding these factors can significantly enhance the longevity and stability of your work, ensuring that your creations stand the test of time.

Selecting the right stainless steel wood screws is not merely about picking a random type off the shelf. It involves evaluating aspects such as the screw's size, thread design, and type of stainless steel used. Each project has its unique requirements, and the correct choice of screws plays a pivotal role in achieving strong joints and safe assemblies. Throughout this guide, we aim to equip you with the knowledge needed to make informed decisions, helping you navigate the myriad options available and ultimately selecting the best stainless steel wood screws tailored to your needs.

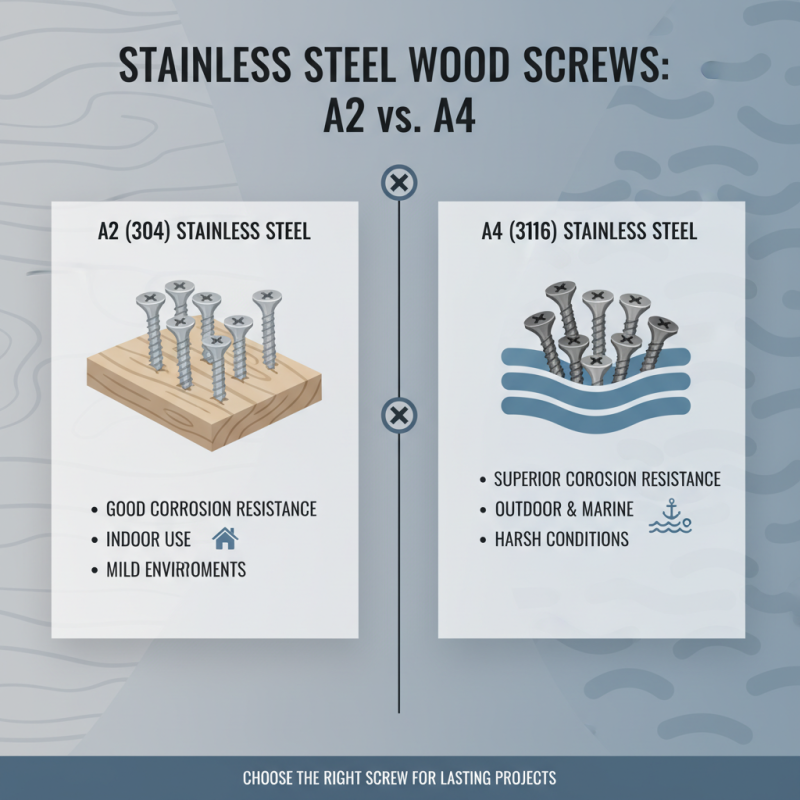

When selecting stainless steel wood screws, understanding the types and grades available is crucial for achieving optimal performance and durability in your projects. Stainless steel wood screws are typically categorized into two primary types: A2 and A4, corresponding to their alloy compositions. A2 screws, also known as 304 stainless steel screws, offer good resistance to corrosion, making them a popular choice for indoor applications and mild environments. In contrast, A4 screws, or 316 stainless steel screws, provide superior corrosion resistance, particularly against saltwater and harsh outdoor conditions, making them ideal for marine applications.

Additionally, the grade of stainless steel plays a significant role in the screw's performance. According to industry reports, the tensile strength of A2 stainless steel is approximately 70,000 psi, while A4 can reach up to 80,000 psi. This strength ensures that the screws can withstand heavy loads without failing, which is essential for structural projects. Choosing the appropriate grade can prevent issues such as rusting and material degradation over time, thereby extending the life of the installation.

**Tips:** Always consider the environmental conditions in which the screws will be used. For coastal areas or projects exposed to extreme moisture, A4 screws are advisable. Furthermore, choosing screws with the correct head type can enhance the ease of installation and ensure a secure fit. Lastly, always verify the diameter and length required for the specific application to achieve optimal holding power.

When selecting stainless steel wood screws, several key factors come into play to ensure you make the best choice for your project. First and foremost, consider the grade of stainless steel. Different grades offer varying levels of corrosion resistance and strength. For outdoor applications or areas exposed to moisture, look for screws made from marine-grade stainless steel, such as 316, which provides superior protection against rust and oxidation.

Another crucial aspect is the screw design. The type of head (like flat, pan, or round) and the thread pattern can significantly impact the screw's performance. For instance, screws with deeper threads can offer better grip in softer woods, while those with finer threads might suit harder materials better. Additionally, consider the length and diameter of the screw, which must match the materials being joined to ensure a secure and lasting connection. Proper pilot drilling and countersinking may also enhance the installation process, leading to more robust results.

In the realm of construction and DIY projects, the application of stainless steel wood screws has become increasingly vital due to their durability and corrosion resistance. According to recent industry reports, the market for stainless steel fasteners is expected to reach $12.4 billion by 2025, signaling a growing reliance on these materials in various sectors. Particularly in environments where moisture is present, such as marine applications or outdoor structures, stainless steel wood screws provide the necessary strength and longevity that other materials may not offer.

Moreover, their versatility extends beyond just structural integrity; stainless steel screws are favored for aesthetic purposes in visible applications. Builders often choose these screws for their clean finish and ability to blend seamlessly with wood, enhancing the overall appearance of the project. As noted in a study by the Fastener Quality Act, utilizing high-quality stainless steel fasteners can significantly reduce the likelihood of rust and degradation over time, making them an ideal choice for both residential and commercial use. Thus, investing in stainless steel wood screws not only contributes to the structural soundness of a project but also supports its visual appeal and long-term performance.

When it comes to selecting fasteners for woodworking projects, stainless steel wood screws stand out for their exceptional durability and resistance to corrosion. According to the Fastener Quality Act, stainless steel fasteners are significantly less prone to rust and degradation compared to traditional steel screws, making them ideal for both indoor and outdoor applications. The introduction of various grades of stainless steel, such as 304 and 316, further enhances their application range, providing options for different environmental conditions.

One of the primary advantages of stainless steel wood screws is their longevity. A study by the American Wood Council indicates that while standard steel screws may start to show signs of rust in just a few months when exposed to moisture, stainless steel can last for years without compromising structural integrity. This makes them not only a cost-effective choice in the long run but also reduces maintenance and replacement costs. Furthermore, their non-reactive properties prevent staining and damage to wood, preserving the aesthetics of your projects, especially in outdoor settings where exposure to elements is a concern.

When it comes to maintaining stainless steel wood screws, understanding the environment in which they will be used is crucial for longevity and performance. In coastal areas, where saltwater exposure is prevalent, opting for screws with a higher corrosion resistance, such as marine-grade stainless steel, is advisable. Regular inspections for signs of rust or degradation will also help in preserving their integrity. Keeping the surface around the screws clean and free from corrosion-causing agents can significantly extend their lifespan, ensuring that the screws function effectively.

In more humid environments, mold and mildew can pose challenges for stainless steel wood screws. To combat this, applying a protective sealant can provide an additional barrier against moisture. Furthermore, it’s beneficial to select screws that are designed with a finish capable of resisting tarnish. Ensuring that wood is properly treated and sealed before installation can also minimize moisture absorption, reducing the risk of screw failure attributed to environmental factors. Each setting demands specific considerations, and by adapting maintenance strategies accordingly, the effectiveness and durability of stainless steel wood screws can be maximized.

This bar chart illustrates key factors to consider when choosing the best stainless steel wood screws in 2025. The criteria include Corrosion Resistance, Strength, Cost, Availability, and Weight, with each metric represented on a scale of 0 to 100.