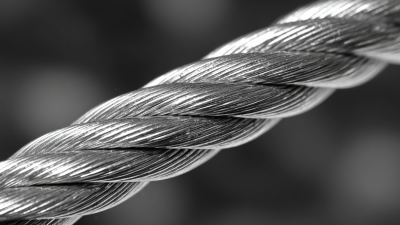

In the rapidly evolving landscape of industrial tools, the wire rope cutter technology is gaining significant attention for its critical role in enhancing operational efficiency and safety across various sectors. According to a recent market report by Smith & Associates, the wire rope cutter market is projected to grow by over 7% annually through 2025, driven by increasing demand in construction and manufacturing industries. This growth highlights the necessity for advanced cutting solutions that not only improve productivity but also adhere to stringent safety standards.

In the rapidly evolving landscape of industrial tools, the wire rope cutter technology is gaining significant attention for its critical role in enhancing operational efficiency and safety across various sectors. According to a recent market report by Smith & Associates, the wire rope cutter market is projected to grow by over 7% annually through 2025, driven by increasing demand in construction and manufacturing industries. This growth highlights the necessity for advanced cutting solutions that not only improve productivity but also adhere to stringent safety standards.

Industry expert Dr. Emily Carter, a leading figure in mechanical engineering and an advocate for workplace safety, emphasizes the importance of innovation in wire rope cutting tools. She states, "The evolution of wire rope cutter technologies is crucial for safeguarding operators while maximizing efficiency in rigorous environments." The development of smarter, more precise cutting tools, such as automated and battery-operated cutters, is setting new standards in the industry. As we approach 2025, understanding the latest technologies and their implications for both performance and safety in wire rope cutting will be paramount for businesses aiming to stay ahead in a competitive market.

The landscape of wire rope cutter technologies is poised for remarkable advancements that promise enhanced efficiency and safety in various applications. With a focus on applied artificial intelligence, advanced computing, and automation, these innovations are set to revolutionize the industry. The future promises an array of cutting-edge solutions, allowing for more precise cutting, reduced waste, and improved operational safety, which are crucial in heavy labor environments where wire ropes are commonly utilized.

The landscape of wire rope cutter technologies is poised for remarkable advancements that promise enhanced efficiency and safety in various applications. With a focus on applied artificial intelligence, advanced computing, and automation, these innovations are set to revolutionize the industry. The future promises an array of cutting-edge solutions, allowing for more precise cutting, reduced waste, and improved operational safety, which are crucial in heavy labor environments where wire ropes are commonly utilized.

Emerging technologies are also playing a vital role in shaping the market dynamics of steel wire ropes. As the industry is projected to grow significantly, reaching a value of $13.88 billion by 2030, the integration of automation in wire cutting operations will become increasingly relevant. These advancements not only enhance production efficiency but also lead to substantial cost savings, allowing companies to optimize their resources effectively while responding to the growing demand for quality and reliability in wire rope applications.

When selecting the ideal wire rope cutter for diverse applications, certain key features stand out notably. First and foremost is the cutting mechanism. Research indicates that hydraulic cutters dominate the market due to their ability to handle thicker cables efficiently. According to a report by MarketsandMarkets, the hydraulic wire rope cutter segment is projected to reach USD 300 million by 2025, reflecting its growing relevance in the industry. Additionally, easy portability is a significant advantage, as some models weigh less than 10 pounds while still providing robust cutting power.

Another crucial aspect to consider is safety features. Cutters equipped with automatic shut-off mechanisms and blade guards not only protect the user but also minimize the risk of accidental injuries. A study by the Occupational Safety and Health Administration (OSHA) found that the implementation of safety features can reduce workplace accidents by up to 30%.

Tips: When purchasing a wire rope cutter, always consider the specific material and thickness the tool is designed to cut. Additionally, prioritize cutters that offer easy maintenance to prolong their lifespan and consistent performance. Always review the manufacturer's safety guidelines to ensure compliance with industry standards.

In the realm of wire rope cutting technologies, safety standards and compliance remain paramount. The development and implementation of advanced cutting methods, such as diamond wire sawing (DWS), highlight a commitment to not only efficiency but also safety in operations. By utilizing innovative techniques, DWS enhances both reliability and performance, particularly in challenging environments like nuclear decommissioning projects. This emphasis on precision and control translates to reduced risks, aligning effectively with stringent safety standards.

Furthermore, adherence to safety regulations in wire rope cutting technologies fosters a culture of responsibility within the industry. As companies explore new cutting solutions, ensuring compliance with national and international safety standards is essential. This includes assessing the operational environments and hazards associated with wire rope cutting, while also integrating cutting-edge technology to improve outcomes. Overall, the intersection of technology and safety standards is crucial for advancing the effectiveness of wire rope cutting practices, ensuring that both efficiency and worker protection are prioritized.

| Technology Type | Cutting Method | Material Compatibility | Safety Features | Compliance Standards |

|---|---|---|---|---|

| Hydraulic Cutters | Hydraulic | Steel, Fiber | Emergency Stop, Pressure Relief | ISO 9001, ANSI B30.11 |

| Electric Cutters | Electric | Steel, Multi-strand | Overload Protection, Safety Guard | CE Marking, OSHA Compliance |

| Manual Cutters | Manual | Steel, Aluminum | Non-slip Grip, Safety Latch | ASTM Standards, EN 60204 |

| Plasma Cutters | Plasma | High-strength Steel | Ventilation System, Heat Shield | ISO 14001, NFPA 70E |

| Laser Cutters | Laser | Steel, Composite Materials | Infrared Sensors, Auto Shut-off | IEC Standards, ISO 50001 |

The comparison between manual and automated wire rope cutters presents a significant shift in operational efficiency and safety in various industries. Manual wire rope cutters have long been the go-to solution, offering portability and ease of use. However, they often require physical exertion and may pose a higher risk of injury due to human error during operation. Moreover, manual cutters can be time-consuming, especially in high-volume environments where quick responsiveness is crucial.

On the other hand, automated wire rope cutters are revolutionizing the cutting process with precision and speed. These advanced systems employ technology to reduce the risk of human error, thereby enhancing workplace safety. Automation not only increases throughput but also minimizes the physical strain on workers, allowing them to focus on more complex tasks. Additionally, the integration of smart technology in automated cutters can provide real-time monitoring and diagnostics, further improving operational efficiency.

**Tips:** When considering wire rope cutters for your operations, evaluate the specific needs of your work environment. If safety and efficiency are paramount, investing in automated options may yield substantial long-term benefits. Always ensure that operators are adequately trained on whichever system you choose to maximize safety and operational performance.

As the industry moves toward automation and advanced technology, the wire rope cutting sector is experiencing a significant transformation. Future trends indicate that smart technologies will play a crucial role in enhancing efficiency and safety in wire rope cutting equipment. Innovations such as IoT (Internet of Things) connectivity allow for real-time monitoring and data analytics, enabling operators to optimize cutting performance and predict maintenance needs. Additionally, the integration of AI-driven systems can assist in identifying the best cutting parameters for various wire rope types, reducing waste and improving productivity.

Tip: Regularly updating your wire rope cutting equipment with the latest smart technologies can significantly reduce downtime and enhance operational efficiency. Consider training your staff on new systems to maximize the benefits of these advancements.

Moreover, advancements in automation are making it possible to achieve precise cuts with minimal human intervention, ensuring consistency while maximizing safety. For instance, robotic arms equipped with advanced sensors can perform cuts in hazardous environments, mitigating risks for personnel. Embracing these smart solutions not only improves safety but also contributes to a more streamlined production process.

Tip: Always prioritize safety by incorporating features like automatic shut-off systems and emergency stop buttons in your cutting equipment to prevent accidents during operation.