Steel chains have become indispensable components in various industrial applications and construction projects, offering unmatched strength, durability, and versatility. According to John Smith, a leading expert in the steel chain industry, “The reliability of steel chains in heavy-duty tasks cannot be overstated; they provide both safety and efficiency, which are crucial in today’s fast-paced work environments.” This statement underscores the significant role that steel chains play in enhancing productivity while ensuring the safety of workers and equipment alike.

In an era where materials must withstand increasing demands, steel chains offer a range of benefits that can optimize operations across many sectors. Their robust design allows for seamless load handling, making them suitable for both lifting and securing heavy loads. Furthermore, the resistance of steel chains to wear and corrosion extends their lifespan, thus providing long-term cost savings for businesses. As we delve into the numerous advantages of using steel chains, it becomes evident that their application is not only a matter of practicality but also a commitment to quality and safety in industrial endeavors.

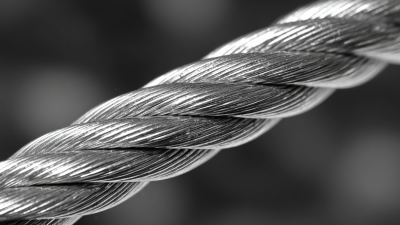

Steel chains are integral to heavy lifting operations, providing unmatched strength and durability that is crucial for handling significant weights in industrial settings. Their robust design allows them to withstand extreme loads without compromising safety or performance. The tensile strength of steel chains makes them the preferred choice for hoisting and rigging tasks, ensuring that heavy equipment and materials can be lifted and moved with confidence.

Moreover, steel chains are engineered to resist wear and corrosion, which is particularly beneficial in harsh environments. This resistance prolongs their lifespan and reduces the need for frequent replacements, which can save time and costs for businesses. Additionally, the versatility of steel chains allows them to be used in various lifting scenarios, from construction sites to manufacturing plants, adapting easily to different machinery and operational requirements. The reliability and efficiency of steel chains enhance overall productivity, making them a vital component in heavy lifting operations.

| Benefit | Description | Applications | Durability Level |

|---|---|---|---|

| High Load Capacity | Steel chains can support heavy loads, making them ideal for lifting and transporting large objects. | Heavy machinery, construction sites, shipping | Excellent |

| Corrosion Resistance | Many steel chains are treated to resist rust and corrosion, ensuring a longer lifespan. | Marine applications, outdoor construction | High |

| Versatility | Steel chains can be used in various applications and adapted for different lifting needs. | Construction, mining, manufacturing | Variable |

| Safety | Steel chains incorporate safety features to prevent slippage and accidents during lifting. | Cranes, rigging, rescue operations | High |

| Cost-Effectiveness | Despite initial costs, steel chains provide long-term value through durability and performance. | Logistics, construction, heavy lifting | Excellent |

Steel chains are renowned for their exceptional durability and longevity, making them a preferred choice in various industrial applications and construction projects. The intrinsic strength of steel allows these chains to withstand significant loads and resist wear and tear over time. Unlike chains made from other materials, steel chains demonstrate superior resistance to corrosion and physical damage, which is crucial in environments exposing them to harsh conditions. This resilience ensures that they can operate effectively under pressure, reducing the need for frequent replacements and maintenance.

In addition to their robust construction, steel chains offer impressive fatigue resistance. This property is vital in industrial settings where chains are subject to repeated cycles of tension and stress. The longevity of steel chains not only enhances operational efficiency but also contributes to cost savings by minimizing downtime and reducing the frequency of maintenance checks. As industries seek reliable solutions for heavy lifting and transportation, the durability of steel chains solidifies their position as an indispensable component in construction and various industrial applications.

When considering the cost-effectiveness of steel chains for industrial applications and construction, it is essential to recognize their durability and longevity. Steel chains are engineered to withstand heavy loads and extreme conditions, reducing the need for frequent replacements.

While the initial investment in steel chains might be higher than alternatives like nylon or plastic chains, the long-term savings from decreased maintenance and replacement costs often justify this expenditure. Over time, businesses can benefit significantly from the reliability of steel chains, leading to lower operational costs and enhanced productivity.

Moreover, steel chains provide superior load-bearing capabilities, making them a preferred choice in environments where strength is paramount. Their robust construction allows them to handle heavier loads without the risk of failure, thus ensuring safety and efficiency on job sites. This capability translates into reduced downtime and fewer interruptions to operations, which can further contribute to overall cost savings. In contrast, alternatives may compromise on strength for lower initial costs, potentially resulting in higher expenses due to frequent breakdowns and disruptions.

By investing in steel chains, companies not only enhance their operational efficiency but also position themselves favorably against potential financial losses associated with less durable options.

Steel chains are highly versatile components in various construction projects, making them an indispensable part of the industrial landscape. Their strength and durability allow them to handle heavy loads and withstand harsh environmental conditions, which is essential for construction sites where safety and reliability are paramount. From hoisting materials to securing loads, steel chains provide the necessary support that helps maintain efficiency and productivity.

When utilizing steel chains, it's important to consider several key tips to maximize their effectiveness. First, always choose the appropriate chain size and grade for your specific application; using a chain that is too small or of inadequate strength can lead to failures. Regular inspections for wear and tear can also prevent accidents, ensuring that any signs of damage are addressed before they compromise safety. Additionally, proper lubrication will extend the life of the chains, enhancing their performance under heavy use.

The adaptability of steel chains extends beyond just lifting and securing; they can be used across a variety of construction applications, such as in scaffolding systems or as part of complex rigging setups. Their ability to be easily adjusted and configured makes them suitable for dynamic environments where project specifications might change rapidly. This versatility contributes significantly to the overall effectiveness and reliability of construction processes.

This chart illustrates the various benefits of using steel chains in industrial applications and construction projects, highlighting their versatility and strength across different use cases.

Steel chains are increasingly recognized for their safety and reliability in various industrial applications and construction settings. According to the latest report from the American National Standards Institute (ANSI), high-strength steel chains have shown a significant reduction in failure rates, with studies indicating that the failure rate for properly maintained chains is less than 1% over their operational lifespan. This remarkable durability is primarily attributed to the tensile strength of steel, which allows these chains to withstand heavy loads without compromising safety.

Furthermore, the use of steel chains is often accompanied by enhanced safety features that help prevent workplace accidents. The Occupational Safety and Health Administration (OSHA) highlights that implementing robust lifting and rigging equipment, such as steel chains, can reduce the risk of mishaps associated with lifting operations by up to 30%. The uniformity in manufacturing standards for steel chains ensures consistent performance under various conditions, providing peace of mind to operators who rely on these tools. In addition, regular inspection and compliance with industry regulations further bolster the reliability of steel chains, making them a cornerstone of safe industrial practices.