When selecting an M10 eye bolt, the choice can greatly affect strength and safety. Experts emphasize the importance of quality in this critical hardware. John Turner, a renowned engineer in the field, states, "A reliable M10 eye bolt can be the difference between safety and disaster."

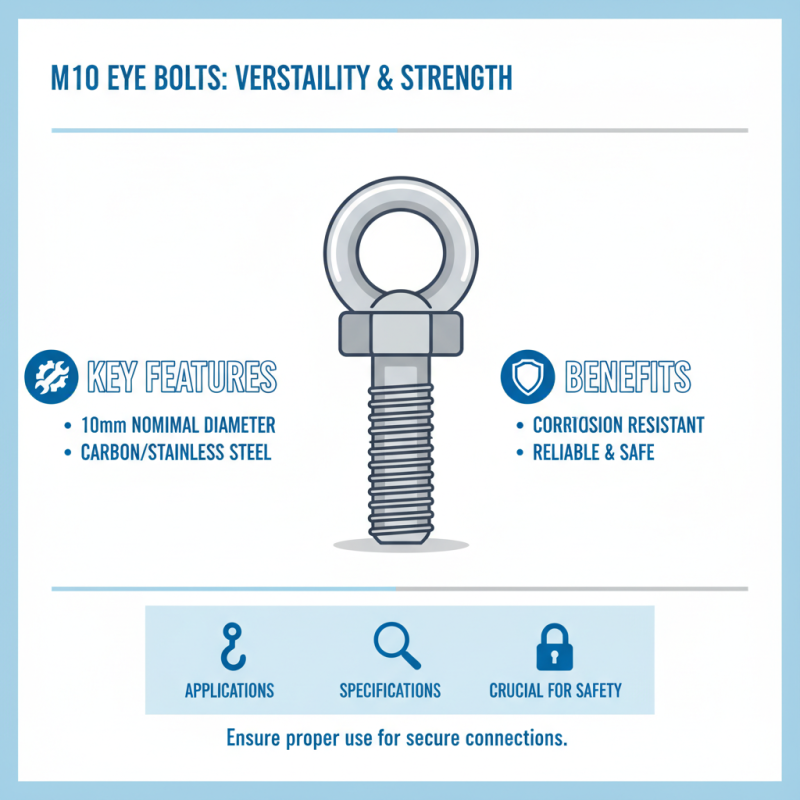

The M10 eye bolt is versatile and widely used. Its applications range from construction to lifting heavy loads. However, many users overlook essential factors. Not every eye bolt meets the same standards. It’s crucial to understand load ratings and material specifications.

In use, proper installation is key. Misalignment or inadequate torque can lead to failure. Reflecting on past experiences, some may not realize the risks until it is too late. Each decision in choosing and using an M10 eye bolt should be made with care. Safety cannot be an afterthought.

M10 eye bolts are popular in various applications due to their versatility and strength. They are typically made from carbon steel or stainless steel, providing resistance against corrosion. The M10 designation means that the bolt has a nominal diameter of 10 mm. Understanding their specifications is crucial for ensuring safety and reliability in usage.

When it comes to strength ratings, M10 eye bolts can support different loads depending on their design and material quality. The standard load rating can range from 1,000 kg to 3,500 kg in ideal conditions. However, it’s important to consider the angle of the applied load. The strength decreases when loads are not applied directly in line with the bolt. Always check the manufacturer's load charts.

**Tip:** Always inspect the eye bolts for wear and tear before use. Small cracks or deformities can significantly reduce their load capacity.

Proper installation is equally important. Ensure that the bolt is anchored securely and that it aligns perfectly with the load direction. Misalignment can lead to unexpected failures, even with properly rated bolts.

**Tip:** Use lock washers to maintain tension and prevent loosening over time. Regular checks can help identify issues before they lead to accidents.

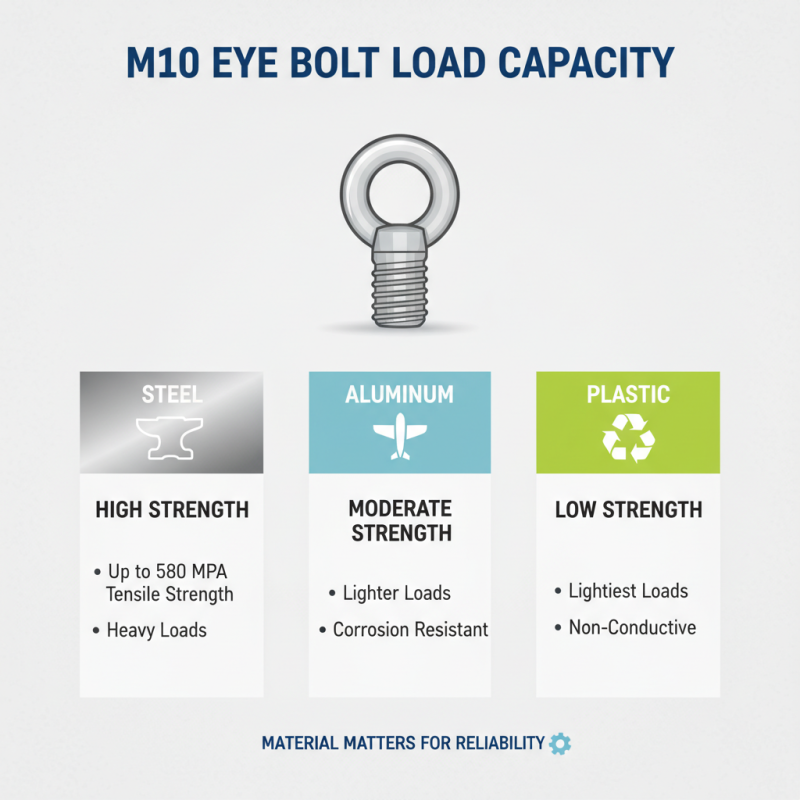

When selecting M10 eye bolts, understanding materials and construction types is essential. Eye bolts are commonly made from steel, stainless steel, and plastic. Steel eye bolts offer high strength and durability but may corrode if not properly coated. Stainless steel provides excellent resistance to rust, making it suitable for marine environments. Plastic eye bolts are lightweight and resistant to corrosion but are less strong compared to metal options.

The construction type of an M10 eye bolt can vary significantly. Forged eye bolts are often stronger than cast ones, which can be prone to weaknesses. Welding plays a crucial role in the construction process. Poorly executed welds may compromise integrity, leading to failures in high-stress applications. Always inspect the bolt before use, checking for cracks or distortions. This attention to detail can prevent accidents and ensure safety.

Choosing the right type of M10 eye bolt requires careful consideration of the specific application. Not all eye bolts are created equal; understanding their limitations is just as important as knowing their strengths. Reflecting on the environment they will be used in will help guide your choice. If unsure, it's worthwhile to seek expert advice or conduct further research.

When selecting M10 eye bolts, understanding the factors affecting their load capacity is crucial. The material of the eye bolt plays a significant role. Steel eye bolts generally support heavier loads compared to those made of aluminum or plastic. According to industry standards, the tensile strength of steel can reach up to 580 MPa, making it a reliable choice for various applications.

Additionally, the thread type and length impact the bolt's strength. Coarse threads typically distribute load better than fine threads. It's important to note that using a shorter thread length may not provide adequate grip in certain materials. Misalignment during installation can lead to premature fatigue, reducing the load capacity significantly. Some engineers recommend using a safety factor of 5:1 for critical applications, ensuring that the eye bolt can handle unexpected stress.

Environmental conditions also matter. Corrosion resistance is vital for eye bolts exposed to moisture. A report from industry experts highlights that galvanized steel can reduce corrosion-related failures significantly. However, even galvanized bolts can deteriorate over time. Regular inspections are advisable. Ignoring these factors could result in catastrophic failures, emphasizing the importance of careful selection and usage.

When installing M10 eye bolts, proper technique is crucial for maximum strength. The American Society of Mechanical Engineers (ASME) recommends a minimum thread engagement of one diameter for optimum load distribution. Ensure that the eye bolt is not threaded too far into the material. Over-threading can weaken the installation.

Concrete and steel are common materials for eye bolt installations. According to a 2022 engineering report, concrete provides a bearing capacity of approximately 3,000 psi. Ensure you select the correct anchor type to match the material structure. For steel, the recommended load capacity can reach about 1,100 kg under ideal conditions. However, many overlook the need for corrosion resistance, especially in outdoor settings.

It's essential to regularly inspect the installed eye bolts. A report from the Institute of Structural Engineers highlighted that neglecting this maintenance can lead to potential failures. Misalignment during installation can cause uneven load distribution, raising the risk of breakage. Thus, continuous evaluation and timely adjustments are key for ensuring safety and effectiveness.

Maintaining M10 eye bolts is crucial for their longevity and effectiveness. Regular inspection is vital to ensure safety and performance. According to industry standards, eye bolts should be inspected for wear, corrosion, and deformation at least every six months. A report from the American Society of Mechanical Engineers highlights that nearly 30% of equipment failures can be traced back to inadequate maintenance.

When conducting inspections, pay close attention to the eye’s opening and shank. Small cracks may go unnoticed, yet they can compromise strength. In optimal conditions, M10 eye bolts can handle loads up to 800 kg. However, improper maintenance could significantly reduce this capacity, creating risks. Keep a log of inspections and maintenance activities. This helps in identifying patterns, which might reveal deeper issues.

In environments exposed to moisture or chemicals, additional care is critical. Consider implementing a more frequent safety check schedule. Many users underestimate the impact of environmental factors. It’s essential to reflect on how these elements might affect the longevity of your eye bolts. Using protective coatings could enhance durability, but remember to check the effectiveness regularly. Each inspection provides an opportunity to reflect on safety and maintenance practices.