When it comes to selecting the ideal stainless steel shackles for your specific requirements, various factors must be taken into account to ensure safety and functionality. According to industry expert Dr. Robert Lang, a long-time engineer in the marine hardware sector, "Choosing the right stainless steel shackle is crucial for maximizing performance and minimizing risks in any application." His insight underscores the importance of understanding the various types, materials, and sizes of stainless steel shackles available on the market.

Stainless steel shackles are integral components used in various applications, from maritime operations to construction and outdoor activities. Their durability and resistance to corrosion make them a popular choice, but choosing the right shackle can be daunting. Factors such as load capacity, working environment, and intended use play a significant role in making the best selection. This guide will provide valuable insights and considerations to help you navigate the options available and ensure that you select the most suitable stainless steel shackles for your needs.

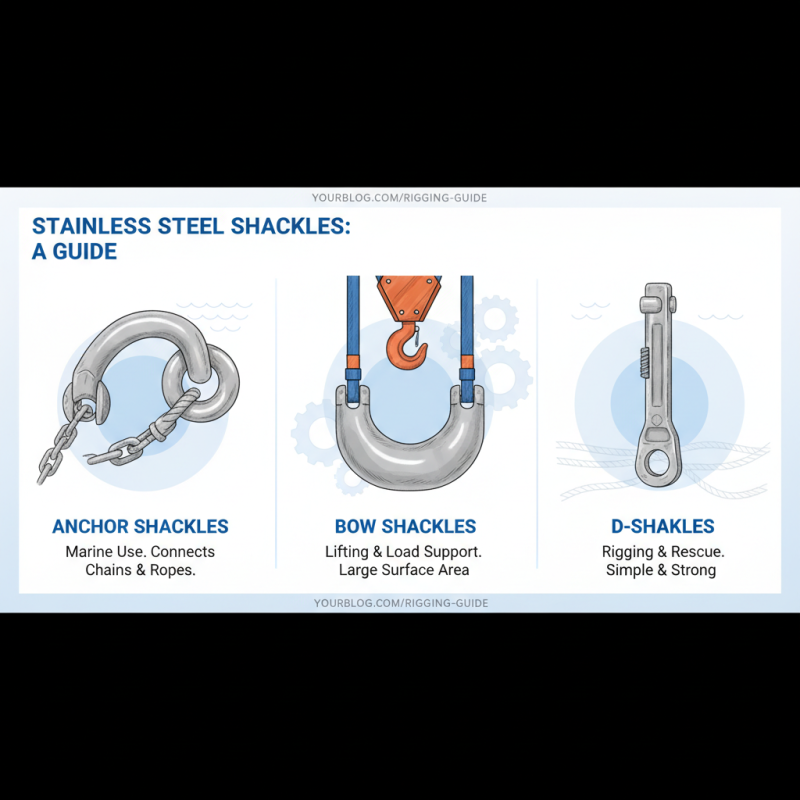

Choosing the right stainless steel shackles starts with understanding the different types available and their specific applications. Generally, there are three main categories of stainless steel shackles: anchor shackles, bow shackles, and D-shackles. Anchor shackles are typically used in marine environments for connecting chain and rope, while bow shackles provide a much larger surface area to support loads, making them ideal for lifting applications. D-shackles, with their straight sides, are commonly used in rigging and rescue operations due to their simplicity and strength.

According to industry reports, stainless steel shackles are rated based on their WLL (Working Load Limit), which varies between 0.5 tons to over 100 tons depending on the size and type. For example, a standard 5-ton stainless steel bow shackle has a significant breaking strength of around 20 tons, making it suitable for heavy-duty applications. Additionally, the choice of material, such as 304 or 316 stainless steel, greatly affects the shackle’s resistance to corrosion, especially in saltwater settings.

Tips for selecting the right shackle include: Always check the weight and load requirements for your specific application, and consider the environment in which the shackle will be used. For marine applications, opt for 316 stainless steel, as it offers superior corrosion resistance. Lastly, ensure to inspect shackles regularly for any signs of wear or deformation, as safety is a primary concern in all lifting operations.

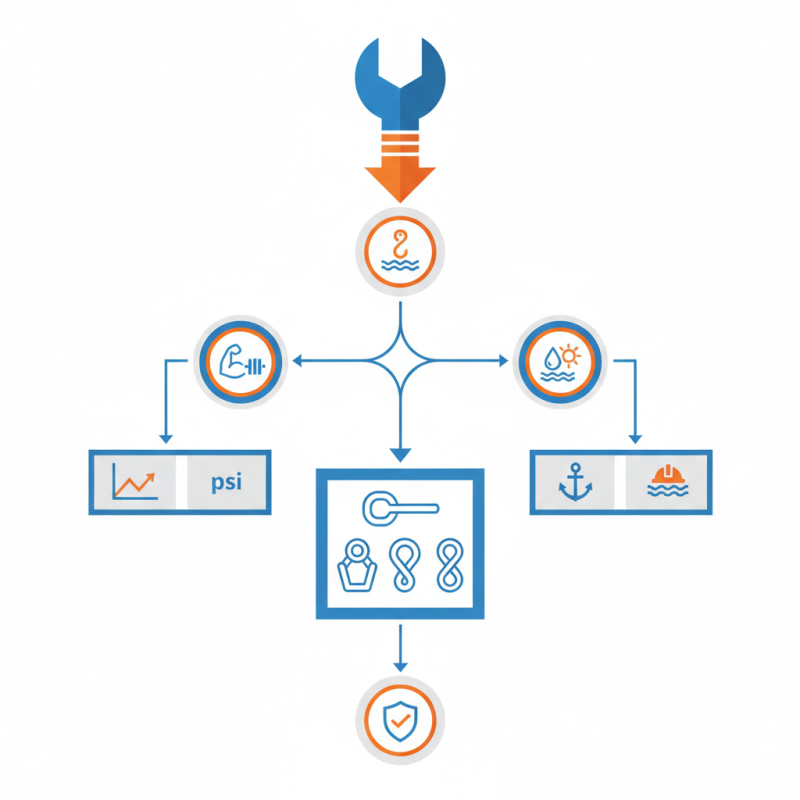

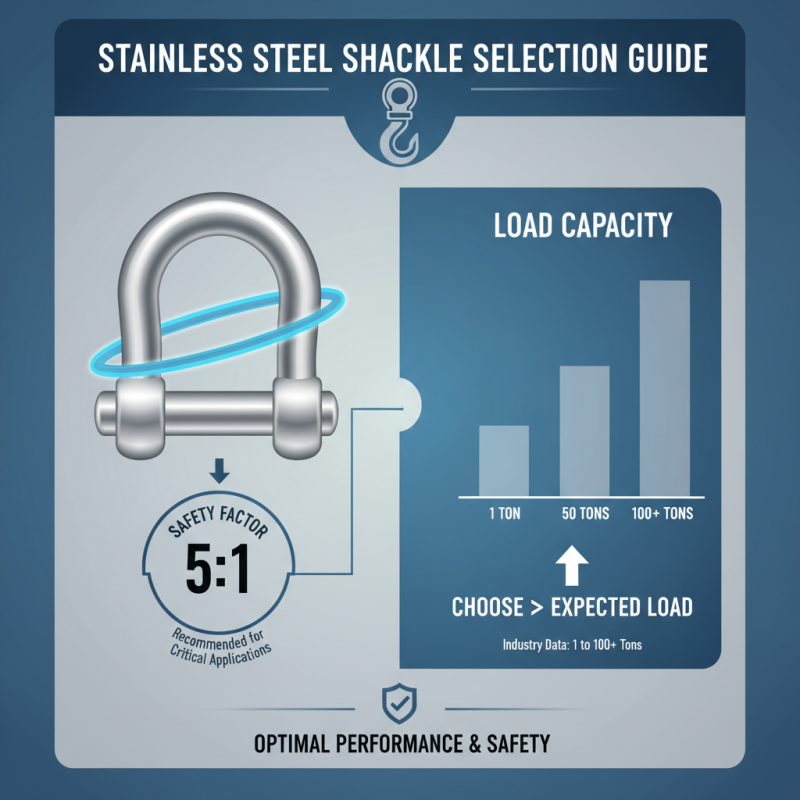

When selecting stainless steel shackles, it is crucial to consider several key factors to ensure optimal performance and safety for your specific applications. One of the most important aspects is the load capacity of the shackle. According to industry data, shackles are typically rated based on their maximum load-bearing capabilities, which can range from 1 ton to over 100 tons. It is essential to choose a shackle that not only meets but exceeds the expected load requirements of your application, as a safety margin of 5:1 is often recommended in safety-critical situations.

Another significant factor to consider is the type of stainless steel used in the shackle's construction. There are mainly two grades of stainless steel that are commonly used: 304 and 316. Grade 316 stainless steel is preferred in marine and harsh environments due to its higher corrosion resistance, which can increase the longevity of the product. Data from the American Society for Testing and Materials (ASTM) indicates that using the appropriate grade of stainless steel can significantly reduce the risk of material failure over time, ensuring that the shackles remain reliable under stress.

Finally, the design configuration—in particular, whether the shackle is a screw pin, a bolt-type, or a quick-release variant—should align with its intended use. A study from the Rigging Industry Association highlights that screw pin shackles are often favored for general use due to their ease of operation and reusability, while bolt-type shackles provide a more secure connection for critical lifting applications. Understanding these factors will help you navigate the selection process effectively and ensure you get the right stainless steel shackle for your needs.

When choosing the right stainless steel shackles, understanding load capacity is crucial. Shackles are typically rated by their maximum load-bearing capacity, which must align with the application they will be used for. First, assess the weight of the load you plan to secure or lift. This number will help you determine the minimum load capacity your shackle must possess. It’s essential to consider not only the weight of the load itself but also any dynamic forces that may occur during lifting or shifting, which can significantly increase the stress on the shackle.

Additionally, safety factors play an important role in determining the appropriate strength for your needs. A good rule of thumb is to select a shackle with a load capacity at least two to three times greater than the maximum expected load. This ensures a margin of safety, accounting for variables such as shock loading, wear over time, and potential miscalculations in weight. Moreover, factors such as the environmental conditions in which the shackle will be used—like exposure to corrosive elements—should also influence your decision, as these can affect the integrity and longevity of the shackle under load.

When selecting stainless steel shackles for specific applications, corrosion resistance is a critical factor to consider. Stainless steel is known for its durability and ability to withstand harsh environments, but not all grades offer the same level of protection against corrosion. The most common grades used in shackles are 304 and 316 stainless steel. While 304 stainless steel provides decent corrosion resistance in mild environments, it may not hold up well in more aggressive conditions, such as marine environments or areas exposed to chemicals.

On the other hand, 316 stainless steel is often recommended for applications requiring enhanced corrosion resistance. This grade contains molybdenum, which significantly boosts its ability to resist pitting and crevice corrosion in chloride environments. Whether it's for marine, industrial, or outdoor use, choosing a shackle made from 316 stainless steel can provide greater peace of mind and longevity in demanding conditions. Therefore, evaluating the specific requirements of your environment is crucial in selecting the right material grade to ensure your stainless steel shackles perform effectively over time.

| Material Grade | Corrosion Resistance | Common Applications | Strength Rating |

|---|---|---|---|

| 304 Stainless Steel | Good | General Purpose, Marine | 6000 lbs |

| 316 Stainless Steel | Excellent | Marine, Chemical Processing | 7500 lbs |

| Grade 70 Galvanized | Moderate | Rigging, Heavy Lifting | 9200 lbs |

| Duplex Stainless Steel | Very High | Oil & Gas, Offshore | 9000 lbs |

| Titanium Alloy | Exceptional | Aerospace, Marine | 5000 lbs |

Proper maintenance and inspection of stainless steel shackles are crucial to ensure their longevity and reliability in various applications. Regular visual inspections should be conducted to identify any signs of wear, corrosion, or damage. Paying close attention to key areas, such as pin connections and the body of the shackle, can help detect issues before they lead to failure. It’s recommended to clean the shackles periodically, especially if used in harsh environments, to remove salt, dirt, and other contaminants that can accelerate deterioration.

In addition to visual assessments, functional checks should also be performed. This includes ensuring that all components, like pins and locks, operate smoothly and without excessive play. Any shackle that shows signs of bending, cracking, or deformity should be removed from service immediately. Documentation of inspection findings can serve as a valuable record to track the condition of shackles over time, guiding maintenance decisions and replacements to maintain safety protocols in the workplace or field.