When it comes to ensuring safety and reliability in rigging applications, the choice of equipment is paramount, particularly in the selection of stainless steel shackles. Stainless steel shackles are widely recognized for their strength, corrosion resistance, and durability, making them a crucial component in various industries, including maritime, construction, and transportation. According to a report by Grand View Research, the global shackles market is projected to reach $2.1 billion by 2025, highlighting the increasing demand for high-quality rigging hardware. A significant portion of this growth is attributed to the rising use of stainless steel shackles, which provide superior performance in harsh environments.

The proper selection of stainless steel shackles involves understanding their specifications, including load capacity, design type, and material grade. Industry standards, such as those set by the American National Standards Institute (ANSI) and the European Committee for Standardization (CEN), emphasize the importance of using shackles that meet rigorous safety and performance criteria. With the right information and guidance, project managers and engineers can make informed decisions, ensuring that the stainless steel shackles they choose not only fulfill the demands of their specific projects but also promote safety and efficiency in operation.

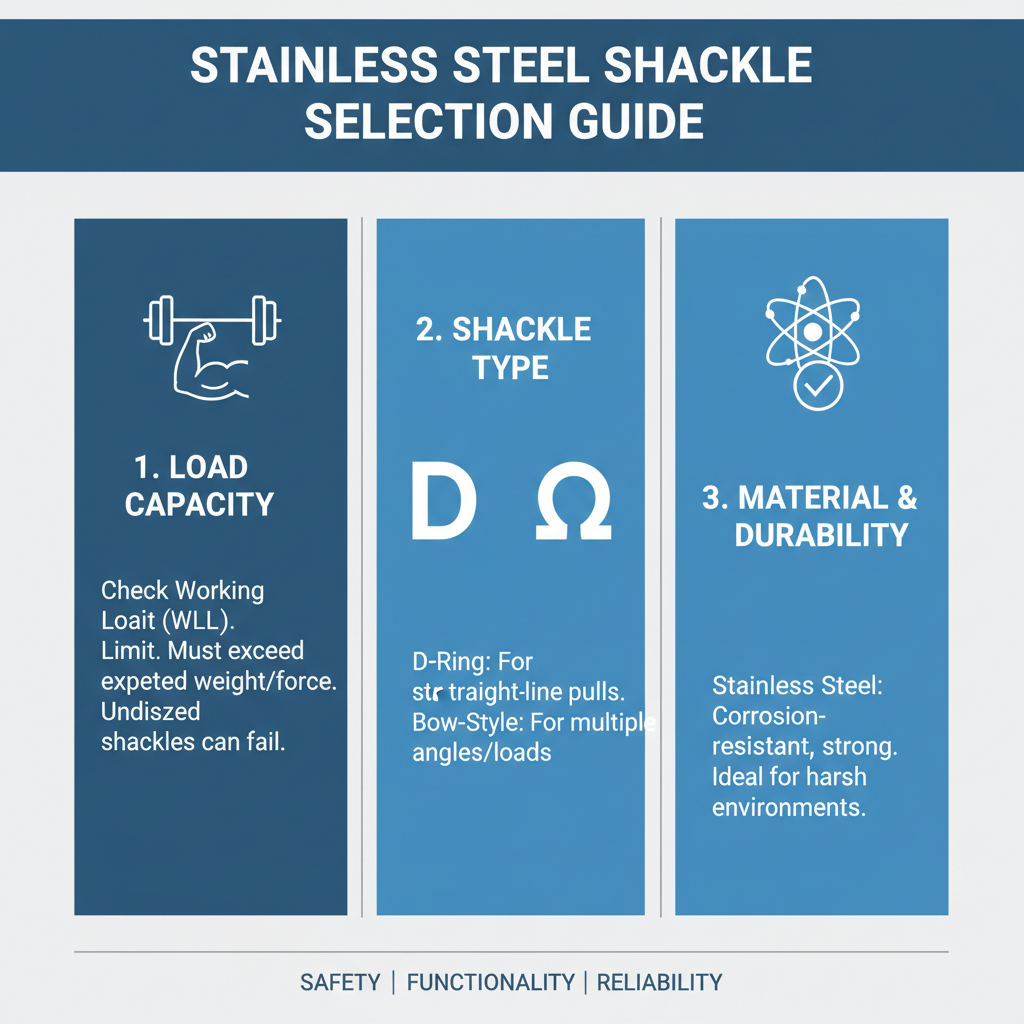

When selecting stainless steel shackles for your projects, it is essential to understand the various types available and their specific applications. Shackles are commonly categorized into two main types: bow shackles and D-shackles.

Bow shackles feature a rounded shape, which provides a larger connection point and distributes the load evenly, making them ideal for applications that require a higher load capacity and flexibility. They are commonly used in sailing, lifting, and rigging scenarios where multiple attachments need to be secured simultaneously.

On the other hand, D-shackles are more compact and offer superior strength in a linear direction. Their design allows for a tighter fit with the load at hand, making them suitable for tasks where space is limited or where a direct pull is required.

They are often used in towing applications or when securing chains and ropes. Understanding the characteristics and strengths of each type of shackle will enable you to choose the right one for your specific needs, ensuring safety and efficiency in your projects.

When selecting stainless steel shackles for your projects, it's crucial to consider several key factors that can impact both safety and functionality. First, evaluate the load capacity of the shackle, ensuring it can withstand the weight and force expected in your application. This includes understanding the working load limits, as using a shackle that is undersized can lead to catastrophic failures. Additionally, consider the type of shackle—D-ring or bow style—as each serves different purposes and has its advantages depending on the configuration of your project.

Another important aspect to contemplate is the environment in which the shackle will be used. Exposure to harsh conditions such as chemicals, saltwater, or extreme temperatures can influence the durability and longevity of the stainless steel. Coatings or finishes may be necessary to enhance corrosion resistance. Finally, assess the design features of the shackle, such as pin type and locking mechanism, which can add an extra layer of safety and ease of use, particularly in high-stress situations. By focusing on these factors, you can ensure that you choose the right stainless steel shackles for your specific project needs.

When selecting stainless steel shackles for your projects, understanding load capacity is crucial. The load capacity indicates the maximum weight a shackle can safely handle, thereby preventing potential failures during operation. According to the American National Standards Institute (ANSI), the working load limit (WLL) of a shackle should be taken into account, where it is typically no more than one-fifth of the ultimate tensile strength (UTS) of the material used. For example, a stainless steel shackle with a UTS of 10,000 pounds would typically have a WLL of 2,000 pounds. This ratio ensures safety and integrity in various rigging applications.

Moreover, choosing the right size of the shackle is equally important, as an incorrectly sized shackle can result in unforeseen stress, leading to component failure. Industry reports suggest that shackles with a WLL exceeding the expected load by a factor of at least five are advisable in industrial settings. This practice not only enhances safety but also improves the durability of the shackle over time, minimizing maintenance requirements. Therefore, a thorough evaluation of the load capacity and appropriate sizing is fundamental when selecting stainless steel shackles to ensure optimal performance in any project.

| Shackle Type | Material | Load Capacity (lbs) | Weight (lbs) | Pin Type |

|---|---|---|---|---|

| Round Pin Shackle | 316 Stainless Steel | 5,000 | 0.75 | Round |

| Bolt Type Shackle | 304 Stainless Steel | 8,000 | 1.2 | Bolt |

| Twisted Shackle | 316 Stainless Steel | 4,000 | 0.5 | Screw |

| D-Shackle | 304 Stainless Steel | 6,000 | 1.0 | Screw |

When selecting stainless steel shackles for your projects, evaluating material quality and corrosion resistance is paramount. The grade of stainless steel used in shackles significantly impacts their durability and performance. Common grades include 304 and 316, with 316 being the preferred choice for marine and highly corrosive environments due to its higher nickel content and added molybdenum, which enhances corrosion resistance against chlorides. For applications exposed to saltwater or chemicals, opting for 316 stainless steel ensures your shackles maintain structural integrity over time.

Aside from the material grade, understanding the manufacturing process also plays a critical role in assessing quality. Look for shackles that have been tested for strength and reliability, with ISO certifications indicating compliance with industry standards. Additionally, check for any protective coatings or treatments that may further enhance corrosion resistance. Proper storage and maintenance are essential to maximize the lifespan of your shackles, so consider environmental conditions and cleaning practices to prevent rust and degradation. By focusing on material quality and corrosion resistance, you can ensure that your chosen shackles will perform effectively in demanding applications.

When selecting stainless steel shackles for your projects, understanding safety standards and certifications is crucial. Shackles are essential components in various lifting and rigging applications, and their quality directly affects safety. Look for shackles that comply with international standards such as ASTM, ISO, or EN, as these certifications ensure that the product has undergone rigorous testing for strength, durability, and reliability.

Tips: Always check the manufacturer's certification and product specifications to ensure compliance with necessary safety standards. Additionally, consider the working load limit (WLL) rated on the shackle to choose one that suits your specific application.

Moreover, various environmental factors can influence the performance of stainless steel shackles, so selecting the right grade of stainless steel, like 304 or 316, is essential. The 316 grade, for instance, offers better corrosion resistance in harsh marine environments, which can be critical depending on the application.

Tips: After identifying the right grade, maintain your shackles properly by cleaning them regularly to prevent corrosion and ensuring they retain their strength and performance over time.