Choosing the right anchor shackle is crucial for various applications. An anchor shackle connects a chain or cable to a load. Its strength and reliability are essential for safety. Different types of shackles serve different needs. For instance, a screw pin shackle is versatile, while a safety shackle provides extra security.

When selecting an anchor shackle, consider material and size. Stainless steel offers corrosion resistance, while carbon steel provides strength. The size must match your chain or strap. Too small can lead to failure, yet too large can be cumbersome.

It's important to reflect on your specific needs. Are you using it for marine applications or construction? Each scenario demands different qualities in an anchor shackle. Investing time in research can ultimately lead to better choices. Remember, the right anchor shackle can enhance safety and efficiency in your tasks.

When selecting an anchor shackle, it’s essential to understand the options available. Shackles come in various shapes and materials. Common types include D-shackles and bow shackles. D-shackles are often used in scenarios requiring strength. Bow shackles, on the other hand, offer more versatility. They can handle multiple attachments with ease.

Material choice is equally important. Stainless steel is popular for its resistance to corrosion. However, it can be heavy. Galvanized steel is another option, more budget-friendly, but might not last as long in harsh conditions. Pay attention to the working load limit. Exceeding it can lead to failure, which could be disastrous.

Size is a crucial consideration as well. Choosing a shackle that is too small can lead to serious safety risks. A shackle that is too big may add unnecessary weight. It's a delicate balance. Reflecting on previous selections can help improve decision-making. Take the time to assess each type before making a choice. The right shackle can ensure safety and efficiency in all operations.

Choosing the right anchor shackle can be challenging. Various factors influence the decision. It's essential to consider the weight and size of the load. A heavy load requires a stronger shackle. The material is also crucial. Stainless steel offers durability, while other materials may not withstand wear and tear.

Different applications demand different shackles. For marine use, corrosion resistance is vital. A shackle exposed to saltwater may degrade quickly. If used in construction, look for options that handle high tensile strength. The shackle's design matters too; a screw pin may provide better security than a hairpin.

Reflect on safety ratings and certifications, as they can differ. An inadequate rating may jeopardize the entire operation. Always check if the shackle meets your needs. It’s easy to overlook these details. Don't rush the decision-making process; haste can lead to mistakes.

When selecting an anchor shackle, material matters significantly. Steel, for example, is robust and budget-friendly. It can handle heavy loads. However, it is prone to rust over time, especially in wet environments. You might find yourself replacing steel shackles frequently if they corrode.

Stainless steel offers better resistance to corrosion. It maintains its strength even in harsh conditions. This can be a more cost-effective choice in the long run. However, it is heavier and more expensive than regular steel. Consider your specific needs before choosing.

Other materials, like aluminum, are lightweight and resistant to corrosion. They may not be suitable for heavy loads but are great for smaller applications. These options often lack the strength of steel or stainless steel. Balancing weight, cost, and durability is key. Reflect on where and how your shackles will be used before making a decision.

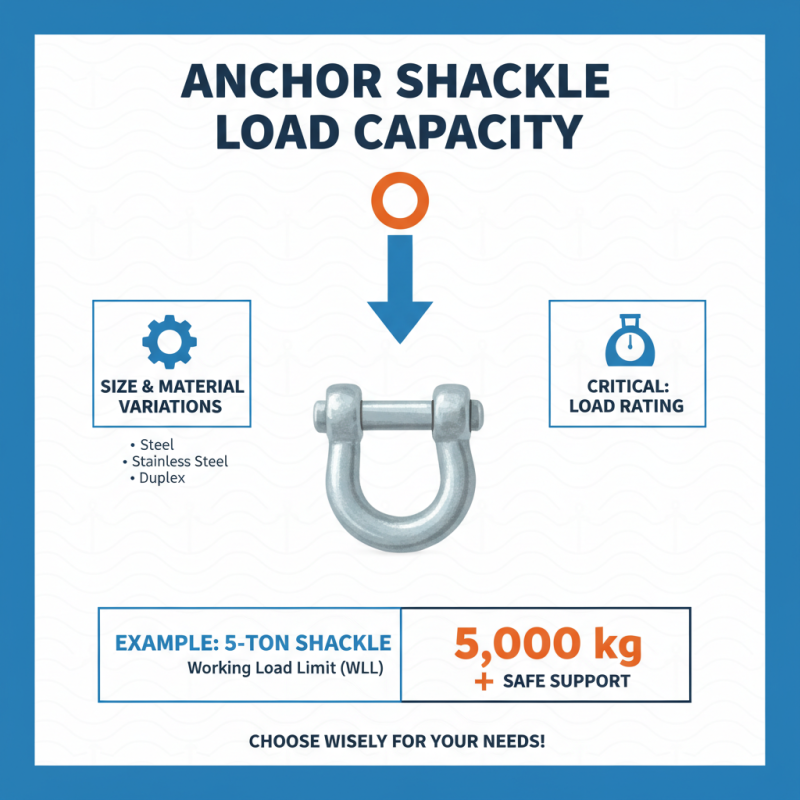

Choosing the right anchor shackle involves understanding its load capacity. Shackles come in various sizes and materials. A critical factor is the load rating, which must align with your specific needs. For instance, a 5-ton shackle typically has a working load limit (WLL) of approximately 5,000 kg. This means it can safely support loads close to this weight.

Industry reports indicate that improper shackle selection can lead to critical failures. For example, using a shackle rated for 2 tons on a load of 3 tons risks breaking under stress. It's essential to consider dynamic loads too; they can increase significantly during lifting or towing. This factor may not be apparent at first glance but can lead to dangerous situations.

Consulting load charts is crucial. These charts provide details on the shackle’s WLL and safe operating practices. Understanding the correct usage is vital. Even experienced professionals can overlook these ratings. The difference between a successful lift and a failure often lies in these details. Remember, a miscalculation could have severe consequences.

When selecting anchor shackles, understanding safety standards is crucial. Industry standards ensure that shackles can withstand heavy loads and adverse conditions. For instance, the American National Standards Institute (ANSI) outlines specific load ratings for various shackle types, ensuring reliability in lifting applications.

Certifications also play a vital role. Products that meet ISO 9001 standards demonstrate that manufacturers have implemented quality management systems. This can assure users of the shackle's integrity. A report by the International Maritime Organization noted that failures due to inadequate certifications accounted for 15% of marine accidents.

Users often overlook the impact of proper certification. Misunderstanding load ratings can lead to serious safety violations. According to industry insights, 20% of shackle failures occur due to misapplication or improper use. This highlights the importance of thorough training and awareness of safety standards. Ignoring these factors can have dire consequences.