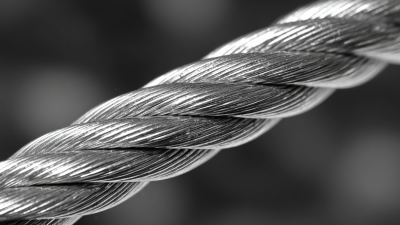

When it comes to choosing stainless steel wire rope, making the right decision is crucial. The global stainless steel wire rope market is projected to grow at a CAGR of 5.6% from 2021 to 2028, according to a recent industry report. This growth highlights the increasing demand for durable and reliable wire ropes in various applications.

Understanding the specific needs of your project is essential. Different industries utilize stainless steel wire rope for various purposes, from construction to marine applications. Each application may require a different type of rope, with varying resistance to corrosion and load capacities. For instance, choosing a wire rope that poorly matches your requirements could lead to safety hazards and costly mistakes.

Furthermore, it's vital to consider factors such as construction methods and diameter when selecting the right stainless steel wire rope. Many overlook the importance of these details, only to encounter issues after installation. Investing time in research can prevent future complications. With the right guidance and knowledge, you can make a well-informed decision that stands the test of time.

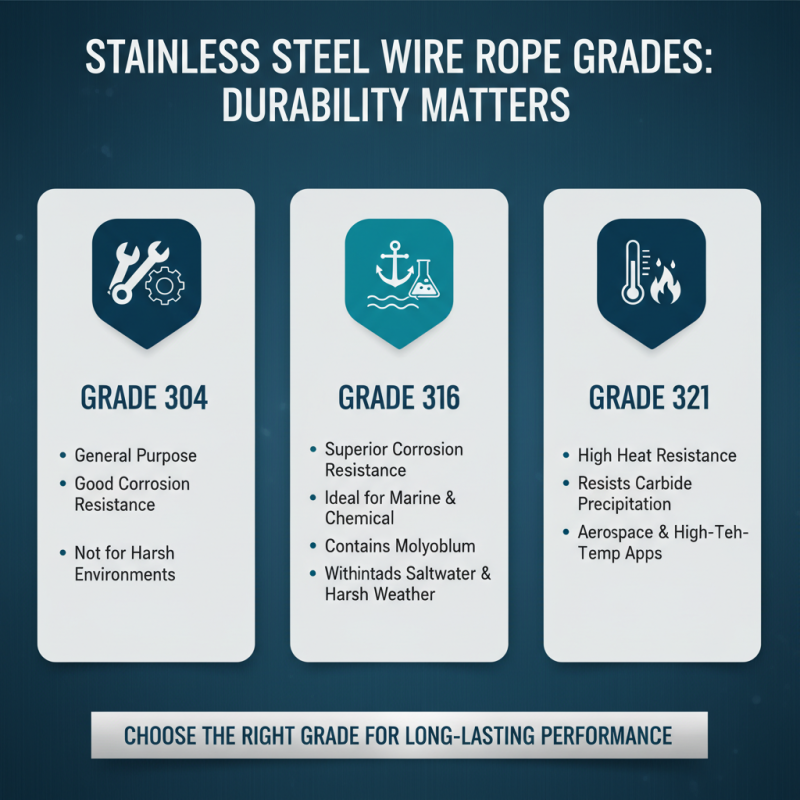

When it comes to stainless steel wire rope, understanding the grades is crucial for ensuring long-lasting durability. Stainless steel wire ropes are typically graded as 304, 316, or 321. Grade 304 is often used for general-purpose applications due to its good corrosion resistance. However, it may not perform well in highly corrosive environments. Studies show that 316 stainless steel, with its added molybdenum, excels in marine conditions. It can withstand saltwater, chemicals, and harsh weather.

Durability is where the grade distinction really matters. Reports indicate that wire ropes made from 316 stainless steel can last up to 50% longer than their 304 counterparts in corrosive settings. Yet, some users overlook the importance of this specification. They may opt for cheaper options, regretting the decision later. 321 grade wire ropes offer better heat resistance but are less common. Understanding these options allows for informed decisions.

Selecting the right grade depends on the specific environment and load requirements. An improper choice can lead to premature wear or even failure. The American Society for Testing and Materials (ASTM) recommends reviewing application requirements carefully. Not all environments are the same, and what works well in one might not in another. This careful consideration is essential for maximizing performance and safety.

Choosing the right stainless steel wire rope involves understanding specific details. The diameter is crucial. Typically, rope diameters range from 1/16 inch to 1 inch or more. A thicker diameter provides greater strength but can be heavier and less flexible. It’s vital to balance strength and handling ease. Most industrial applications recommend a diameter that suits both the load and environment.

Construction type also matters. There are several types of wire rope constructions, like 7x19 or 1x19. Each offers different flexibility and strength characteristics. For instance, a 7x19 construction provides more flexibility, suitable for dynamic movements. However, it’s worth noting that increased flexibility can reduce the overall load capacity.

Load capacity is another key specification. Knowing the working load limit (WLL) helps in selecting the right wire rope. Data indicates that a 1/4 inch 7x19 stainless steel wire rope typically has a WLL of around 1,600 pounds. However, different environments can affect performance. Factors like temperature, corrosion, and installation method play significant roles. Hence, a careful assessment is necessary to ensure safety and longevity.

When choosing stainless steel wire rope, understanding the environmental factors is crucial. Corrosion resistance is key in various conditions. Different grades of stainless steel exhibit distinct properties. For instance, Type 304 is often used due to its good corrosion resistance in general environments. However, its performance degrades in marine settings. Here, Type 316 excels due to added molybdenum, which enhances protection against saltwater.

Consider the environment where the wire rope will be used. Humidity, temperature, and exposure to chemicals significantly affect durability. The surface finish of the wire also plays a role. A smooth finish can offer better resistance than a rough one. Harsh environments, like coastal areas or chemical plants, may require specialized options. No one-size-fits-all approach exists in wire rope selection.

It's also essential to evaluate maintenance needs. Even the toughest wire ropes can corrode without proper care. Regular inspections help catch early signs of wear. Ignoring this can lead to costly failures. Reflecting on these factors ensures a more informed choice. After all, the right wire rope can save time and frustration in the long run.

When selecting stainless steel wire rope, adhering to safety standards is crucial. Various regulations govern the use of wire ropes in industries like construction and marine. Compliance ensures a safe working environment. There are many standards to consider, such as those set by organizations that focus on material strength and tensile requirements.

Each region may have specific guidelines. In some places, the wire rope must pass rigorous testing. Ignoring these standards can lead to serious accidents. It's essential to check for certifications and documentation before purchase. Moreover, regular inspections are necessary to ensure ongoing safety. Even a slight wear or corrosion can compromise strength.

Determining the right type of wire rope also involves understanding its intended use. Different applications require different specifications. For example, marine environments might need additional corrosion resistance. Not every wire rope is suitable for all tasks. This misstep can have dire consequences. Always consult experts when in doubt. Investing time in understanding these regulations and standards is vital for safety and reliability.

Choosing the right stainless steel wire rope goes beyond the initial purchase. Proper maintenance is crucial for ensuring longevity and optimal performance. Regular inspections help identify early signs of wear and damage. Look for fraying, corrosion, or rust. These issues, when ignored, can lead to significant failures.

There are essential tips for maintaining wire rope:

Consider the storage method as well. Improper storage can cause twisting or kinking, which affects performance. Store wire rope in a dry place, avoiding sunlight. Regularly rotate the rope to prevent uneven wear. Learning and implementing these practices requires reflection on past experiences. Neglecting maintenance can be costly and detrimental.