In the world of materials engineering, selecting the right stainless steel can be a pivotal decision for the success of any project. Particularly, 316 stainless steel stands out due to its exceptional resistance to corrosion and pitting, making it suitable for marine environments and applications that require high durability. According to expert metallurgist Dr. Jane Holloway, “Choosing the right grade of stainless steel, especially 316 stainless steel, significantly impacts the longevity and performance of your projects.”

Understanding how to identify and choose the best 316 stainless steel for your needs is essential for engineers, architects, and builders alike. With an array of options available in the market, the characteristics of 316 stainless steel, such as its composition and mechanical properties, play a crucial role in ensuring that your project meets both aesthetic and functional requirements. This guide will explore the key factors to consider when selecting 316 stainless steel, helping you make informed decisions that contribute to the success of your endeavors.

316 stainless steel is renowned for its exceptional resistance to corrosion, making it an ideal choice for projects exposed to harsh environments. This alloy contains molybdenum, which enhances its durability and resistance against pitting and crevice corrosion, particularly in chloride environments like marine applications. Its ability to withstand elevated temperatures and its excellent tensile strength further contribute to its versatility in various industrial applications.

In addition to its strong corrosion resistance, 316 stainless steel also offers superior workability and formability. This makes it suitable for a wide range of fabrication techniques, from welding to machining. The smooth surface finish of 316 stainless steel not only improves its aesthetic appeal but also prevents the accumulation of dirt and bacteria, making it a favored material in the food and pharmaceutical industries. Its combination of resilience, durability, and hygiene ensures that 316 stainless steel stands out as a reliable option for both structural and decorative applications in challenging environments.

When selecting the best 316 stainless steel for your projects, it is crucial to understand its key properties. 316 stainless steel is known for its exceptional corrosion resistance, particularly against chlorides and chemicals, making it ideal for marine environments, chemical processing, and food production. This steel alloy contains molybdenum, which enhances its durability compared to other stainless steels. Additionally, its excellent formability and weldability make it a versatile choice for various construction and manufacturing applications.

Tips: When assessing 316 stainless steel, consider the environment in which it will be used. For instance, in coastal areas or applications exposed to harsh chemicals, ensure that the material's corrosion resistance specifications meet your project needs. Additionally, evaluate the mechanical properties such as tensile strength and yield strength to ensure the steel will perform under the expected loads.

Another essential factor is the finish of the stainless steel. A higher finish can impact both aesthetics and performance, as a smoother surface can reduce the buildup of contaminants, which is particularly important in food handling and pharmaceutical industries. Be sure to discuss your project requirements with suppliers to obtain the best surface finish for your application.

When choosing the best 316 stainless steel for your projects, it’s essential to understand the different grades available. The most common grades of 316 stainless steel include 316L, 316H, and 316Ti, each designed to meet specific needs and requirements. 316L is low in carbon, making it an excellent choice for welding applications due to its resistance to sensitization. This grade is well-suited for environments where corrosion resistance is paramount, such as marine or chemical industries.

On the other hand, 316H is known for its high-temperature strength, making it ideal for applications that require durability under elevated heat conditions, such as in power generation or chemical processing. Meanwhile, 316Ti, which has added titanium, offers enhanced stability at high temperatures and resistance to intergranular corrosion. Choosing the right grade depends on factors like environmental conditions, temperature variations, and the mechanical stress involved in your project, ensuring optimal performance and longevity of the finished product.

| Grade | Corrosion Resistance | Tensile Strength (MPa) | Applications | Weldability |

|---|---|---|---|---|

| 316 | Good | 515 | Marine environments, chemical processing | Good |

| 316L | Excellent | 505 | Low carbon applications, welding | Excellent |

| 316H | Good | 515 | High temperature applications, petrochemical | Good |

| 316Ti | Good | 520 | High-temperature applications, food processing | Good |

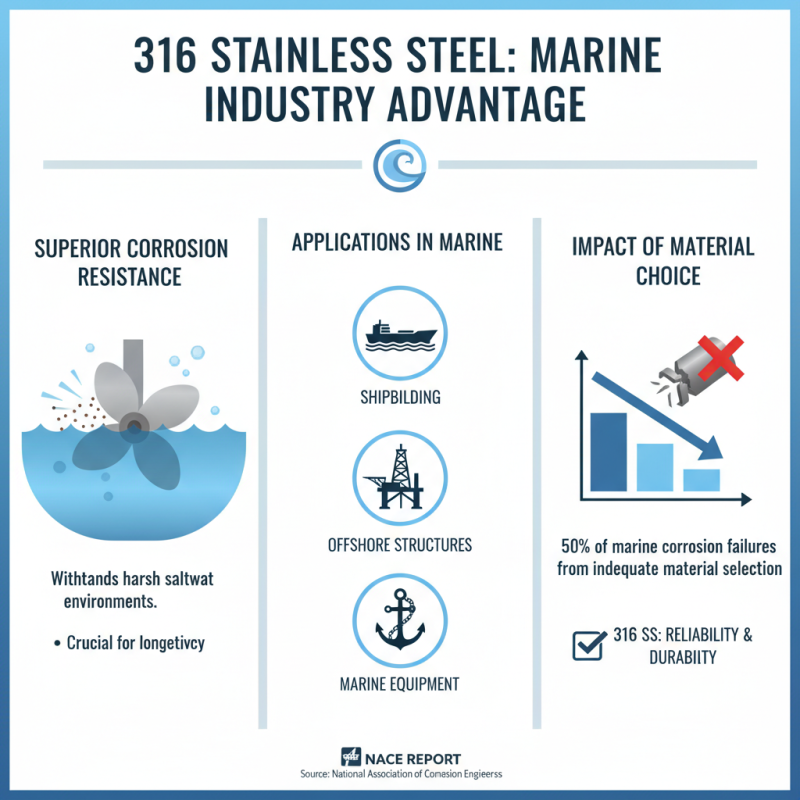

316 stainless steel, known for its superior corrosion resistance and durability, is widely utilized across multiple sectors. In the marine industry, for instance, its ability to withstand harsh environments makes it the material of choice for shipbuilding, offshore structures, and marine equipment. According to a report by the National Association of Corrosion Engineers (NACE), approximately 50% of corrosion-related failures in marine applications can be attributed to inadequate material selection. Therefore, 316 stainless steel's resistance to saltwater corrosion is crucial in maintaining the integrity and longevity of various maritime structures.

In the pharmaceutical and food processing industries, 316 stainless steel is essential due to its hygienic properties and ability to withstand high temperatures. The American Society of Mechanical Engineers (ASME) notes that this grade of stainless steel is favored in sanitary applications for equipment such as tanks and piping, significantly reducing the risk of contamination. Furthermore, studies have shown that using 316 stainless steel can lead to a decrease in product spoilage rates by as much as 20%, underlining its importance in ensuring product safety and compliance with health regulations. Its versatility and performance make it indispensable in these critical sectors.

When it comes to safeguarding and maintaining 316 stainless steel products, understanding the material's corrosive resistance is crucial. According to a report by the International Stainless Steel Forum, 316 stainless steel contains molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments, making it ideal for marine applications and chemical processing plants. Regular maintenance practices, such as routine cleaning and inspection, are essential to prolong the life of these products. Cleaning with mild detergents and avoiding abrasive materials can significantly reduce the risk of damage.

Furthermore, to maintain the aesthetic and functional properties of 316 stainless steel, it is essential to regularly check for signs of corrosion or wear, which can occur due to inadequate maintenance or environmental stress. The American Society of Mechanical Engineers emphasizes the importance of proactive measures, advising that any visible signs of corrosion should be addressed immediately to prevent further deterioration. By ensuring proper maintenance protocols are followed, including passivation treatments and the use of protective coatings when appropriate, users can ensure that their 316 stainless steel products maintain their integrity and performance for years to come.