Wire rope clamps are essential components in various industries, providing safe and secure connections for wire ropes used in lifting, rigging, and suspension applications. According to industry reports, improper use of wire rope clamps can lead to catastrophic failures, resulting in injuries and significant financial losses. The Occupational Safety and Health Administration (OSHA) emphasizes that nearly 30% of rigging-related accidents arise from equipment malfunction, much of which can be traced back to incorrect installation or maintenance of wire rope clamps.

To mitigate these risks, understanding the correct application and installation methods for wire rope clamps is vital. Research indicates that a well-installed wire rope clamp can improve the overall stability and safety of lifting operations. For instance, the Wire Rope Technical Information System (WRTIS) states that when properly utilized, wire rope clamps can enhance the load capacity of a wire rope by 25% or more, reinforcing their critical role in ensuring reliable and efficient operations across sectors such as construction, marine, and transportation.

As industries continue to grow and evolve, ensuring that all personnel are trained in the proper use of wire rope clamps is paramount. With safety regulations becoming increasingly stringent, equipping workers with the knowledge to use these tools effectively not only promotes workplace safety but also enhances productivity and operational efficiency.

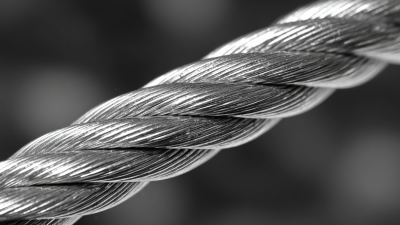

Wire rope clamps are essential tools used to secure the ends of wire rope, ensuring strong and reliable connections in various applications. Typically crafted from durable materials like steel, these clamps work by firmly gripping the wire rope and preventing slippage, which is critical in both lifting and rigging operations. Understanding the anatomy of a wire rope clamp—including its saddle, U-bolt, and nuts—is crucial for effective use. The saddle should always rest on the portion of the rope that is under the load, while the U-bolt provides the necessary clamping force to secure the rope.

In addition to lifting and rigging, wire rope clamps find applications in a range of industries, from construction to marine environments. They can be used to create loops in cables for mooring boats, hanging equipment, or securing structures. Given the varied uses, it's important to select the appropriate size and type of clamp for the specific wire rope being utilized. Proper installation and inspection are equally vital; any sign of wear or improper connection can lead to catastrophic failures. Educating personnel on installation techniques and regular inspections can greatly enhance safety and efficacy in any operation where wire rope clamps are employed.

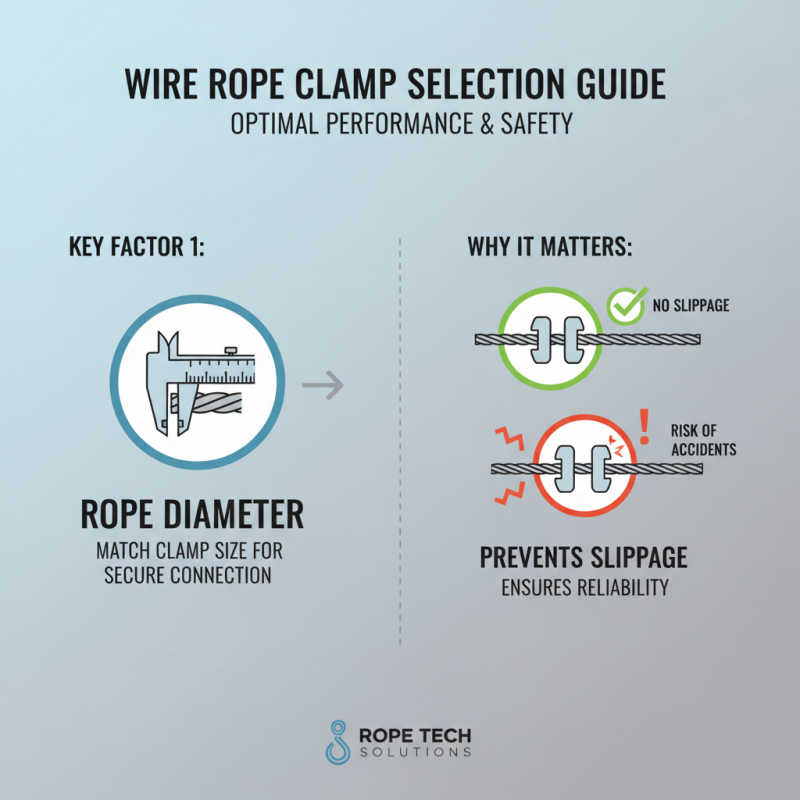

When selecting the right wire rope clamp for your needs, it's essential to consider several key factors to ensure optimal performance and safety. First and foremost, assess the diameter of the wire rope you are working with. Wire rope clamps come in various sizes, and a proper fit is crucial for achieving a secure connection. Using a clamp that corresponds with the rope size minimizes the risk of slippage and potential accidents during operations.

Another important consideration is the material of the wire rope clamp. Clamps are typically made from various metals, such as steel or aluminum, each offering distinct advantages. For instances where corrosion resistance is essential, opting for stainless steel clamps may be wise, particularly in marine or highly humid environments. Additionally, the workload capacity of the clamp should align with the application requirements. Always consult load charts or guidelines to select a clamp that can withstand the specific forces it will encounter during use, thereby ensuring a reliable and safe connection.

Installing a wire rope clamp correctly is crucial for ensuring reliable and safe connections in any rigging or lifting operation. According to industry standards, using the right number of clamps is essential; most applications recommend at least two clamps for secure jointing of two rope ends, with an additional clamp for heavier loads. The spacing between each clamp should be consistent, typically 6-8 rope diameters apart. This method distributes the load evenly across the clamps, minimizing the risk of failure.

To begin the installation, first, lay the wire rope on a flat surface and form a loop at the joint. Place the wire rope clamps around the loop, ensuring that the “U” shape of the clamp is facing the dead end of the rope, which helps in securing the connection. Tighten the nuts gradually in a criss-cross pattern, applying torque as per the manufacturer’s specifications, which are typically around 40-50% of the wire rope’s break strength. It is advisable to perform a load test after installation to verify the clamps' integrity, as data shows that improper installation can lead to a failure rate of up to 30% in critical applications. By following these guidelines, you can ensure safe, reliable, and durable connections when using wire rope clamps.

| Step | Description | Tools Needed | Safety Tips |

|---|---|---|---|

| 1 | Select the appropriate wire rope clamp size for your application. | Clamp set, measuring tape | Ensure the clamp is rated for the rope diameter. |

| 2 | Prepare the wire rope by cleaning and cutting it to the desired length. | Cutting tool, cleaning cloth | Wear gloves to protect your hands while cutting. |

| 3 | Insert the wire rope through the wire rope clamp's saddle. | Wire clamp | Ensure the rope lays flat in the saddle for a secure fit. |

| 4 | Position the U-bolt over the wire rope and place the nuts on the other side. | Wrench | Tighten nuts evenly to avoid damaging the rope. |

| 5 | Tighten the nuts to the specified torque rating. | Torque wrench | Check for proper tightness and inspect for any damage. |

| 6 | Perform a load test to ensure the connection is secure. | Load testing equipment | Always stand clear while testing the load capacity. |

When using wire rope clamps, safety should always be the top priority. Before starting any project involving wire rope, it’s crucial to inspect both the clamp and the rope for any signs of wear or damage. A damaged wire rope or clamp can lead to catastrophic failure, posing risks to both operators and bystanders. Always ensure that the clamp is suitable for the diameter of the wire rope being used; using an incorrect size can result in inadequate grip and stability.

Tips for Safe Use:

Maintaining and inspecting wire rope clamps is crucial for ensuring the safety and longevity of rigging systems. According to industry standards, regular inspections can prevent catastrophic failures that result from wear and tear or improper installation. The American National Standards Institute (ANSI) recommends that wire rope clamps be inspected for any signs of corrosion, cracks, or deformation before each use, especially in high-load applications. An alarming statistic from the Occupational Safety and Health Administration (OSHA) indicates that improper rigging contributes to approximately 70% of accidents in the construction sector. This highlights the importance of diligent maintenance and inspection.

To extend the life of wire rope clamps, handlers should follow a systematic maintenance routine. Applying a protective lubricant can help reduce friction and protect against corrosion. Reports from the National Association of Manufacturers (NAM) suggest that a proactive maintenance approach can extend the lifespan of these components by up to 30%. Furthermore, clamps should be cleaned regularly to prevent grime accumulation, which can contribute to deterioration over time. The necessary spacing between the clamp and the wire rope must be verified, as improper spacing is a common cause of failure. By adhering to these practices, users can ensure safer operations and reduce the risk of accidents related to wire rope failures.