When it comes to securing heavy loads and ensuring the integrity of various applications, understanding the proper use of a wire rope clamp is essential. Wire rope clamps are vital components in many industries, as they provide strong and reliable connections when utilizing wire ropes. However, improper installation or selection can lead to serious safety hazards and inefficiencies in operations. It is crucial to recognize the key techniques and best practices for effectively utilizing wire rope clamps to maximize their benefits and ensure durability.

In this guide, we will delve into the fundamental aspects of wire rope clamps, including the principles of their design and function. We will also explore the critical steps involved in installation, maintenance tips, and common mistakes to avoid. By following these guidelines, users can enhance safety and performance in their applications, ultimately promoting a more secure working environment. Understanding how to properly use a wire rope clamp not only contributes to operational efficiency but also plays a vital role in risk management and safety compliance.

Wire rope clamps are essential tools used in various applications to create secure connections in wire rope assemblies. Understanding the different types of wire rope clamps and their specific uses is crucial for achieving optimal performance and safety. Typically, there are two main types of wire rope clamps: U-bolt clamps and forged wire rope clips. U-bolt clamps are easy to install and are often used for temporary connections, while forged wire rope clips offer greater durability and load-bearing capacity, making them suitable for more permanent applications.

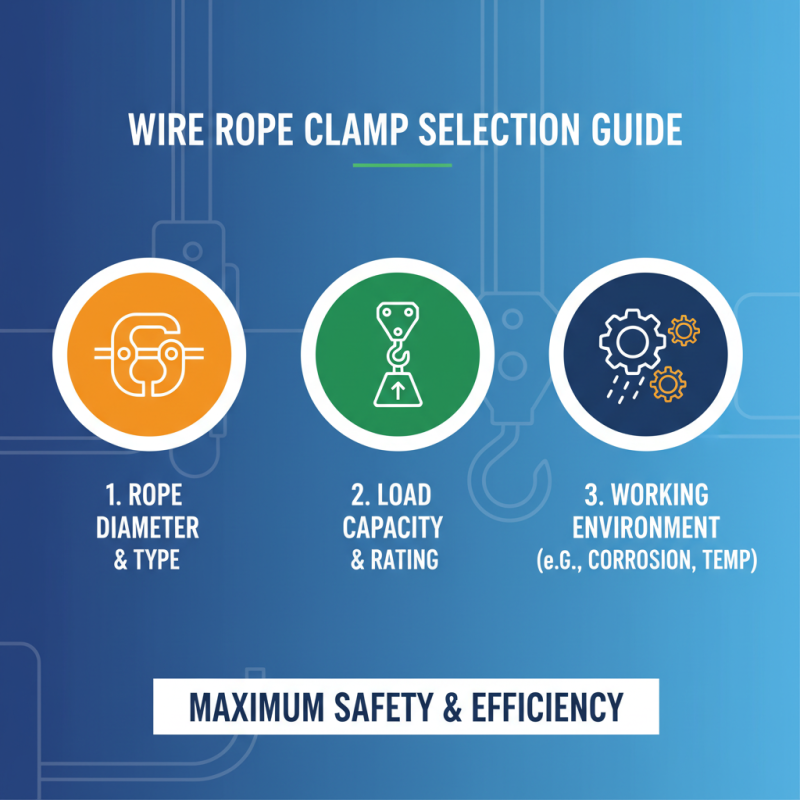

The choice of a wire rope clamp also depends on the diameter of the wire rope being used and the load it will carry. For lighter loads or non-critical applications, standard U-bolt clamps may suffice. However, for heavy-duty lifting or rigging tasks, it’s advisable to use forged clips with proper installation techniques. Each type of clamp has its load ratings, and adhering to these ratings is essential for safety. Furthermore, it's imperative to ensure that the clamps are installed correctly to prevent slippage or failure, which can lead to hazardous situations. Understanding these nuances allows for safer and more effective use of wire rope clamps in diverse industrial and recreational environments.

When selecting the right wire rope clamp for your application, it's essential to consider factors such as the diameter of the wire rope, the load capacity, and the working environment. Wire rope clamps are designed to securely hold wire ropes at various angles and configurations, so choosing the correct type ensures maximum safety and efficiency. For example, if you're working with heavy loads or harsh conditions, a heavy-duty clamp made from corrosion-resistant materials may be necessary to provide long-lasting durability.

Tips for selecting wire rope clamps include measuring the wire rope diameter accurately to ensure a snug fit, which helps to avoid slippage. Also, consider the number of clamps required; typically, more clamps provide a stronger grip but may increase the complexity of the connection. Always refer to manufacturer guidelines for load ratings and installation instructions, as improper use can compromise the safety of your setup. Additionally, when in doubt, consulting with a professional or an experienced colleague can provide valuable insights tailored to your specific needs.

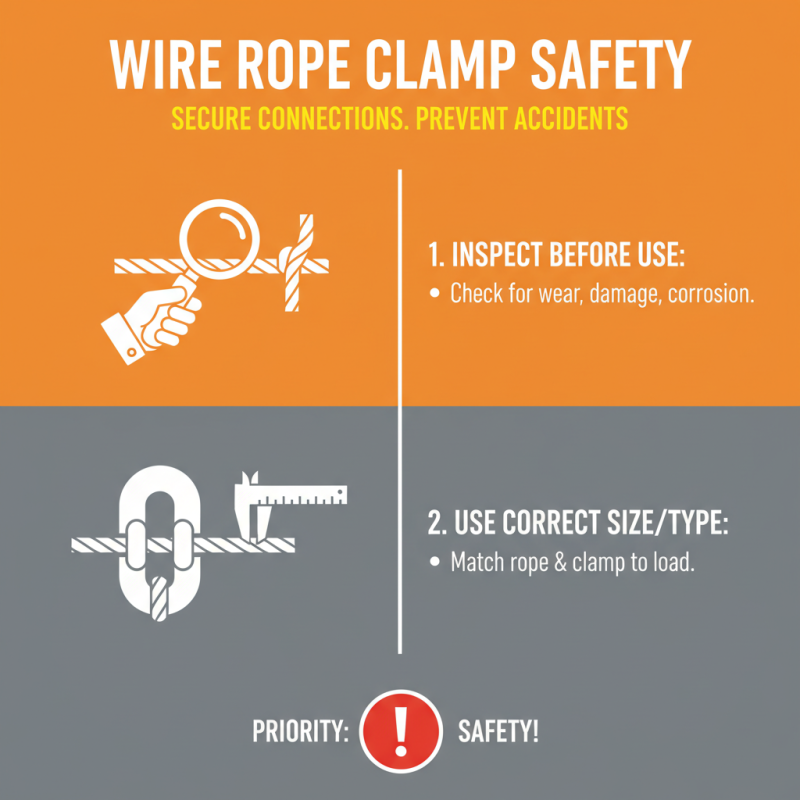

Another important tip is to inspect the clamps regularly for signs of wear or damage, especially in high-stress applications. A small crack or deformation can lead to catastrophic failures if overlooked. By taking the time to select the right clamp and maintain it properly, you can ensure secure connections and enhance the overall safety of your wire rope assemblies.

Installing a wire rope clamp correctly is essential for ensuring secure connections and preventing accidents. Begin by gathering your materials, including the wire rope, the clamps, and a reliable set of tools. First, determine the required length of wire rope, and then cut it appropriately. When you have your wire in place, create a loop to form a connection point. This will often involve making sure that the wire is doubled back on itself to provide a stable base for securing with the clamps.

Next, position the wire rope clamps into place, ensuring that the saddle of the clamp is on the live side of the rope, while the U-bolt is on the dead side. This orientation is crucial for optimal grip and performance. Tighten the bolts evenly and in a crisscross pattern to distribute the pressure evenly across the wire. It's important to not overtighten, which can damage the wire rope. After securing the clamps, it is a good practice to re-check their fitting after a short operational period to ensure they remain tight and effective. Following these steps will lead to a strong, reliable connection using wire rope clamps.

| Step | Description | Tools Required | Safety Tips |

|---|---|---|---|

| 1 | Select the appropriate wire rope clamp size for your wire diameter. | Wire rope clamps, measuring tape. | Always wear safety goggles. |

| 2 | Position the wire rope in a U-shape under the saddle of the clamp. | None required. | Ensure the clamp is facing the right direction. |

| 3 | Place the bolt and nut over the wire rope and tighten it. | Wrench or socket set. | Do not overtighten to avoid damaging the wire rope. |

| 4 | Repeat the process with additional clamps if necessary for secure connections. | Wire rope clamps, measuring tape. | Check all connections before use. |

When using wire rope clamps, safety should be the utmost priority to prevent accidents and ensure secure connections. First and foremost, always inspect the wire rope and clamps before use. Look for any signs of wear, damage, or corrosion, as these can compromise the strength of the connection. Ensure that the wire rope is of the appropriate size and type for the intended application, as using the wrong specifications can lead to failures under load.

Moreover, during installation, it is crucial to follow the correct procedure for securing the wire rope. Always ensure that the clamp is installed in the proper orientation, with the saddle on the live end of the rope and the U-bolt on the dead end. This configuration maximizes the clamp's effectiveness and helps prevent slippage. Additionally, use the correct number of clamps for the diameter of the wire rope—typically at least two clamps for a secure connection. Finally, after installation, perform a load test to verify that everything is secure before putting it into operation. Taking these safety precautions can significantly reduce the risk of accidents when using wire rope clamps.

Maintaining and inspecting wire rope clamps are crucial steps to ensure their longevity and reliability. Regular checks should be conducted to identify any wear or damage that could compromise the integrity of the connection. Begin by examining the clamps for signs of rust, corrosion, or deformation. Pay particular attention to the bolt threads; any stripping could indicate over-tightening or fatigue. It’s also important to inspect the wire rope itself for strands that are frayed or broken as these issues directly affect the performance of the clamp.

In addition to routine visual inspections, it’s advisable to implement a maintenance schedule that includes cleaning and re-tightening the wire rope clamps as necessary. This not only promotes optimal performance but also extends the life of the clamps. Use a suitable lubricant to prevent corrosion and facilitate ease of adjustment. When reinstalling or adjusting, ensure that the clamps are positioned correctly to maintain even distribution of pressure, thereby enhancing their holding strength. By prioritizing these maintenance practices, the longevity and reliability of wire rope connections can be significantly improved.