In the world of rigging and lifting equipment, understanding the importance of a reliable wire rope clamp is crucial for safety and efficiency. According to industry expert John Stevens, a leading authority on cable and rigging systems, “The right wire rope clamp not only ensures the integrity of the lift but also minimizes the risk of accidents.” This statement underscores the significance of selecting high-quality clamps that meet industry standards.

Wire rope clamps serve as vital components in various applications, from construction sites to maritime operations. They are designed to securely fasten wire ropes together, preventing slippage and providing peace of mind during high-stakes operations. With numerous options available on the market, distinguishing the best from the rest can be a daunting task.

In this comprehensive guide, we will explore the top ten wire rope clamps, delving into their specifications, applications, and performance metrics. Armed with the latest industry statistics and expert insights, you will gain valuable knowledge to make informed choices that enhance your operational safety and efficiency. Join us as we navigate through the essential aspects of wire rope clamps and their critical role in your industry endeavors.

Wire rope clamps play a crucial role in ensuring safety and performance in various applications, particularly in construction, shipping, and rigging. These essential devices are used to secure wire ropes and prevent slippage, which could lead to severe accidents or equipment failure. Understanding the proper selection and installation of wire rope clamps is fundamental for maintaining the integrity of lifting and hoisting systems. A well-chosen clamp can withstand significant loads and environmental stresses, ensuring reliable performance under pressure.

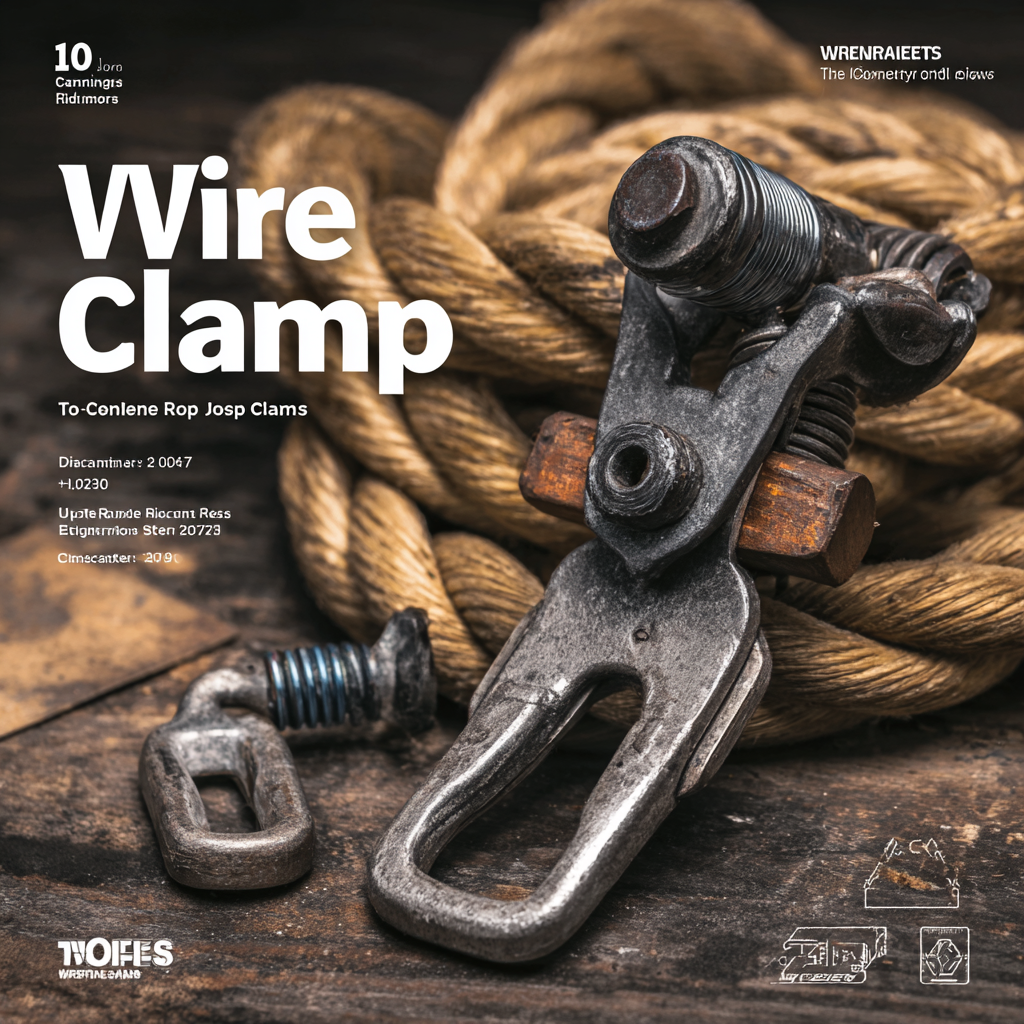

When evaluating wire rope clamps, the material and design are paramount. Clamps are typically made from steel or aluminum, with different designs, such as U-bolt or wedge-type clamps, catering to specific needs. It’s essential to match the clamp to the rope's diameter and intended usage, as a poor fit can compromise safety. Additionally, regular inspections and maintenance of wire rope clamps can prevent premature wear and failure, reinforcing their vital role in safeguarding both personnel and equipment during operations.

When selecting wire rope clamps for your project, several key features should be considered to ensure optimal performance and safety.

One of the primary aspects is the material of the clamp. High-quality wire rope clamps are typically made from galvanized steel or stainless steel, offering resistance to corrosion and extending service life, especially in harsh environments.

According to a report by the International Wire & Cable Conference, using corrosion-resistant materials can improve the longevity of wire rope systems by up to 30%.

Another important feature is the design and application of the clamps. Clamps should be engineered to bear the load specific to your project’s requirements.

The Wire Rope Technical Board suggests that using a clamp rated for at least twice the working load limit of the wire rope can significantly reduce the risk of failure.

Additionally, the configuration of the clamp plays a vital role in maintaining a secure grip on the wire, with double-saddle designs often recommended for enhanced holding power and stability.

Lastly, consider the ease of installation and maintenance. Some clamps are designed with user-friendly installation systems that minimize the need for special tools, making them convenient for projects where time efficiency is crucial.

Industry statistics indicate that ease of installation can reduce labor costs by up to 20% on large projects, highlighting the importance of choosing the right clamp for your needs.

When it comes to wire rope clamps, understanding the different types and their specific applications is crucial for ensuring safety and efficiency in various industries. Wire rope clamps are generally categorized into two main types:

single-saddle and

double-saddle clamps.

Single-saddle clamps are often used for lighter loads and are easier to install, making them suitable for domestic applications such as securing garden swings or small lifting devices.

In contrast, double-saddle clamps provide greater load stability and are typically used in heavy-duty settings where securing large or critical loads is essential.

The choice of wire rope clamp depends not only on the type of load but also on environmental factors and safety requirements. For instance, clamps designed for marine environments often come with corrosion-resistant materials to withstand harsh conditions.

Additionally, industries such as construction or climbing utilize specialized clamps tailored to the unique stresses encountered in those fields.

Understanding these differences can help in selecting the right clamp for your specific needs, ultimately enhancing performance and safety in any application.

Wire rope clamps play a crucial role in various industries, providing secure connections for wire ropes in lifting, rigging, and suspension applications. Understanding the performance of these clamps is essential for ensuring safety and efficiency. Industry statistics reveal that improper installation is a leading cause of failure, accounting for approximately 30% of wire rope-related accidents. This emphasizes the importance of training and following best practices during installation to mitigate risks.

Another common challenge faced by professionals in the field is wear and corrosion, which can significantly decrease the lifespan of wire rope clamps. Studies have shown that up to 40% of clamps are replaced prematurely due to environmental conditions such as moisture and chemical exposure. To combat this, selecting the right materials and finishes for clamps is vital. Stainless steel or galvanized options can enhance durability and resist corrosion, making them preferable choices in harsh conditions.

Proper installation and maintenance of wire rope clamps are essential for ensuring safety and efficiency in various industrial applications. According to a recent report from the American Society of Mechanical Engineers (ASME), approximately 60% of wire rope failures stem from improper installation. To mitigate this risk, it is crucial to follow standardized practices, such as ensuring the clamps are positioned correctly on the wire rope with the saddle on the dead end. The recommended gap between the clamp and the wire should be at least 1.5 times the wire diameter to prevent slippage and ensure optimal holding power.

In terms of maintenance, routine inspections are vital. The Wire Rope Technical Board suggests that wire rope clamps should be inspected at least once every three months or more frequently in high-stress environments. Signs of wear or corrosion can indicate a need for immediate replacement. Regular maintenance not only extends the life of the wire rope and clamps but also enhances workplace safety, aligning with OSHA guidelines that advocate for proactive risk management strategies in industrial settings. By adhering to these best practices, companies can significantly reduce the likelihood of accidents and costly downtime, thereby improving overall productivity.