Square U bolts are essential components in various projects and applications across industries. In the words of John Smith, a leading expert in fasteners, “Square U bolts provide strength and versatility that other shapes simply can’t match.” This statement captures the heart of why these bolts are in demand.

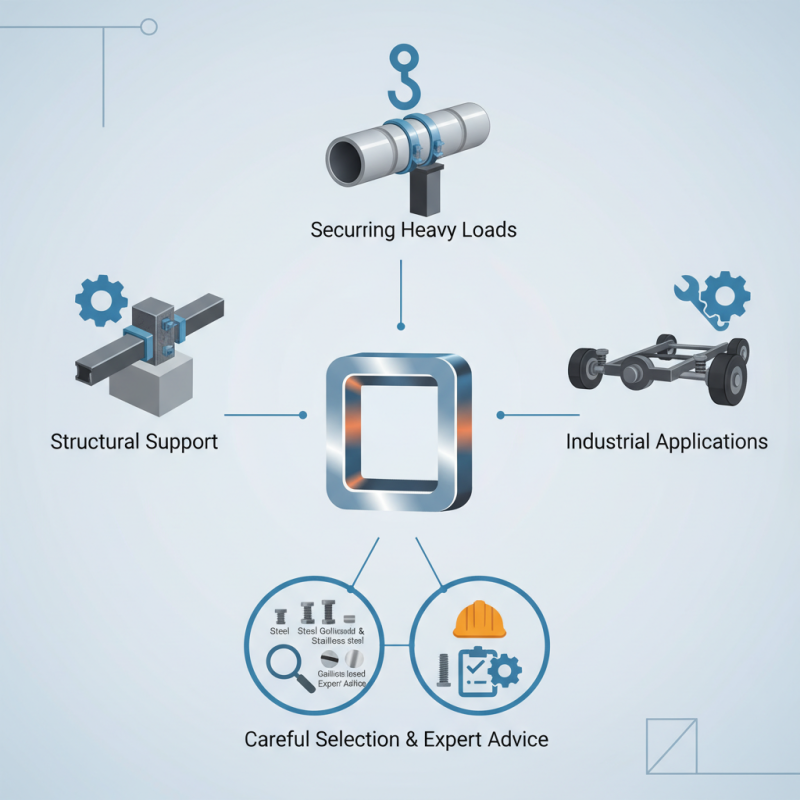

Many professionals consider square U bolts for structural support and securing heavy loads. These bolts excel in applications requiring stability. However, improper installation or selection can lead to issues. It's crucial to assess your project's specific needs before choosing a size or material.

Understanding the nuances of square U bolts enhances your project's success. Their design allows for a secure fit, reducing the risk of loosening over time. Yet, choosing the wrong bolt type could compromise safety. Careful deliberation and expert advice can guide you to make the right choice for your needs.

Square U bolts are essential components in various applications, especially in construction and automotive industries. They provide strong support and stability. Their unique shape allows for a tight fit around pipes and poles. This is crucial for ensuring safety and durability.

Understanding the specific applications of square U bolts can enhance your projects. These bolts are often used to secure items in place. They can hold down exhaust systems or help with electrical installations. However, selecting the right size is vital. A mismatch can lead to structural failures. Pay attention to weight limits. Sometimes, people overlook small details, leading to regrets later.

Installation of square U bolts requires careful attention. Improper installation can lead to safety risks. It is important to use the correct tools and techniques. Many users struggle with this aspect. A little research can go a long way. Reflecting on past mistakes can guide future projects. Ultimately, the goal is to achieve both functionality and safety in your applications.

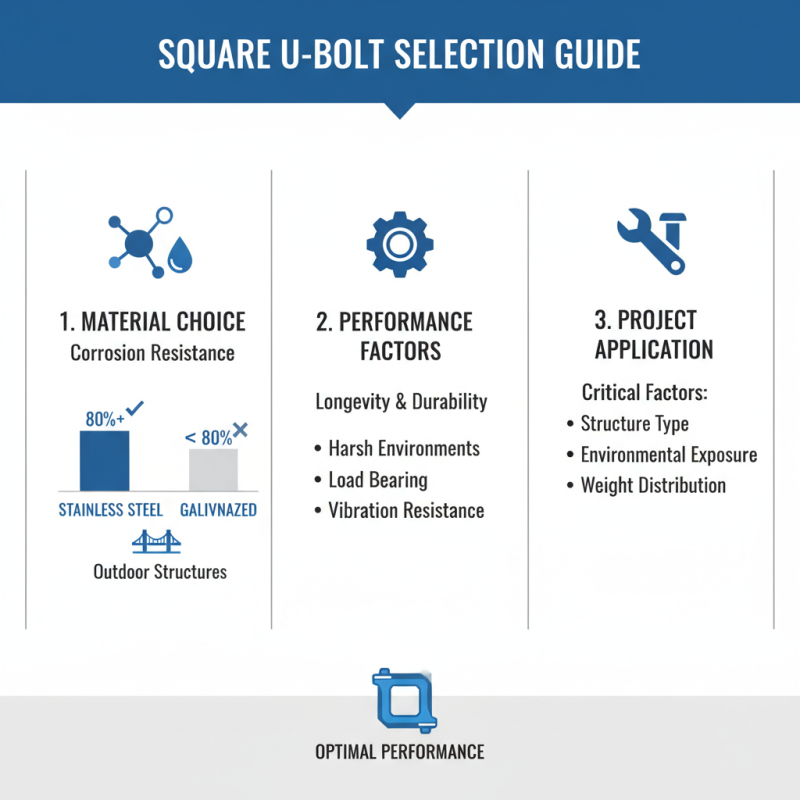

When selecting square U bolts, several critical factors play a significant role in ensuring optimal performance for your projects. The material choice is essential, as corrosion resistance can affect longevity. According to industry reports, stainless steel U bolts outperform their counterparts in harsh environments, with a corrosion resistance of over 80% compared to galvanized options. For outdoor structures, this can make a noticeable difference in durability.

Another factor to consider is the load capacity of the U bolt. The correct load rating is vital to prevent failures. Research indicates that approximately 20% of U bolt failures occur due to incorrect load requirements. Understanding the specific application requirements can aid in choosing the right size and strength.

Also, the installation process should not be underestimated. Proper torque specifications can prevent loosening or breakage. Some project managers report frequent issues related to improper torque, resulting in unanticipated repairs. A focus on these factors can lead to better project outcomes. It’s a reminder that attention to detail is crucial. Ignoring these can lead to costly mistakes.

When selecting square U bolts for your projects, materials and coatings are crucial. Choosing the right materials ensures strength and longevity. Stainless steel is often preferred for its excellent corrosion resistance. It withstands harsh environments, making it ideal for outdoor applications. However, it can be more expensive than other options.

Galvanized steel is another solid choice. This coating provides a barrier against rust. It's often used in construction and automotive applications. But the coating can wear down over time, especially in humid conditions. Regular maintenance may be necessary to prolong its life.

Plastic coatings are gaining attention. They offer additional protection and come in various colors. These coatings create a barrier against scratches and impacts. Yet, they may not be suitable for high-temperature environments. It's essential to weigh these factors when making your selection.

Consider your specific application and environmental conditions. Making an informed choice can lead to better project outcomes.

Square U bolts are versatile fasteners used across various industries. They provide strong and reliable connections for different structures. Their unique shape allows them to distribute loads evenly and offer exceptional stability. This makes them popular in construction, automotive, and agricultural applications.

In construction, square U bolts secure beams and brackets effectively. They withstand vibrations and heavy loads, ensuring safety. In automotive applications, they connect parts like axles and suspensions. Their resistance to rust makes them ideal for outdoor use. Agriculture also benefits; they are used to attach trailers and secure fencing.

Tip: Always choose the right size and material for your needs. Incorrect sizing can lead to failure. Double-check measurements before purchasing. If you’re unsure, consult with an expert. It’s better to invest time in planning than to face costly mistakes later. Remember, even small oversight can lead to significant issues.

| Dimension (inches) | Material | Finish | Common Applications |

|---|---|---|---|

| 1/4 x 2 | Steel | Zinc Plated | Automotive, Construction |

| 3/8 x 4 | Stainless Steel | Mirror Finish | Marine, Structural |

| 1/2 x 6 | Carbon Steel | Black Oxide | Heavy Machinery, Construction |

| 5/16 x 3 | Alloy Steel | Galvanized | Farming, Industrial |

| 3/4 x 8 | Stainless Steel | Passivated | Construction, HVAC |

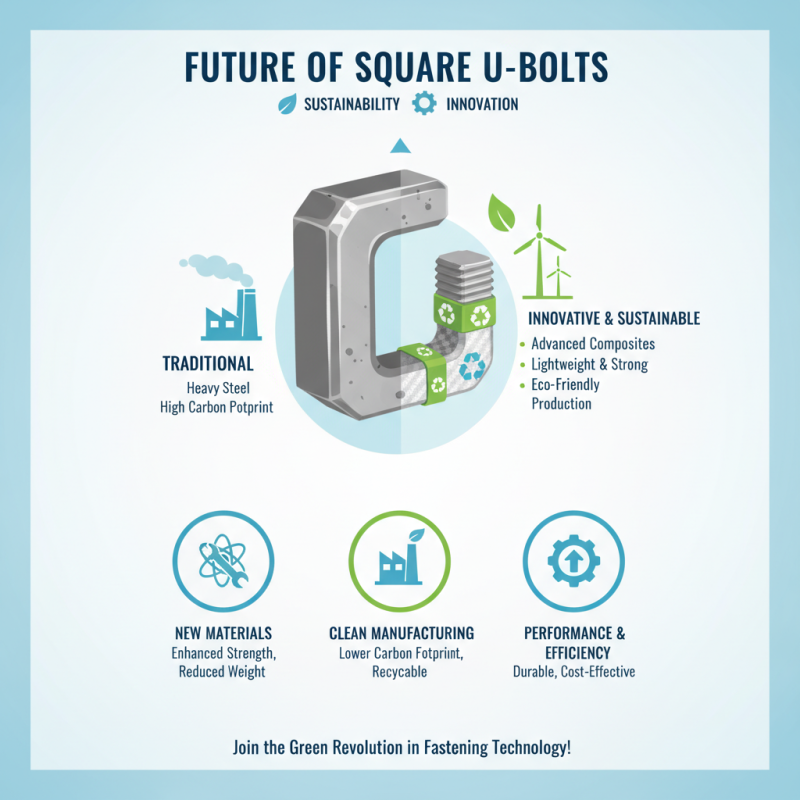

The future of square U bolt design and manufacturing is evolving rapidly. Companies are focusing on innovation and sustainability. New materials are being introduced, enhancing strength while reducing weight. The trend leans towards environmentally friendly production methods. This shift aims to lower the carbon footprint of manufacturing processes.

Tips for selecting square U bolts include considering the specific application. Assess load requirements carefully. Match the bolt's material to the environment it will be exposed to. Corrosion resistance can be vital for longevity. Ensure that the dimensions fit your project needs precisely. Customization options are becoming more common, so explore them.

Designing square U bolts with advanced technology is crucial. Automation speeds up production, but it may cause inconsistencies. Regular quality checks are essential to maintain standards. There's a challenge in balancing efficiency and precision. Continuous feedback loops within the manufacturing process can help refine designs over time.