In the realm of industrial applications, the stainless chain plays a critical role. These chains are renowned for their durability and resistance to corrosion. However, choosing the right stainless chain can be challenging. Various factors influence their performance and longevity.

Consider the specific requirements of your operation. Weight load, environment, and exposure to chemicals can all impact the effectiveness of a stainless chain. Not all chains are created equal, and the wrong choice may lead to failure. Over time, users often overlook important details, leading to unexpected issues.

In this guide, we will explore the top stainless chains of 2026. You'll discover what to consider when selecting a stainless chain. It's essential to make informed decisions to enhance operational efficiency. This knowledge could save time and resources in the long run. Let's dig deeper into this topic together.

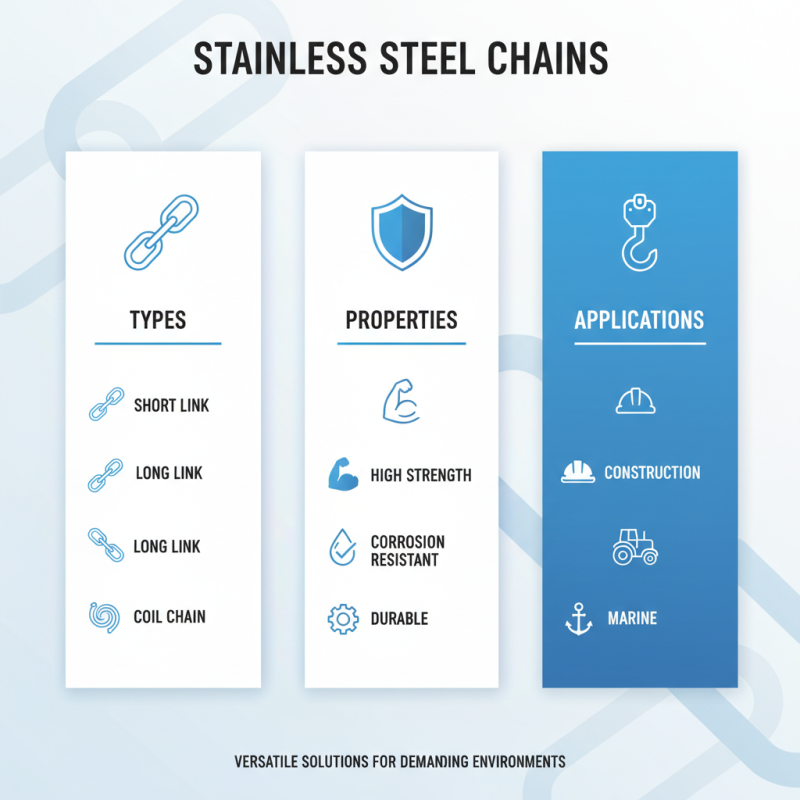

Stainless chains come in various types and serve multiple applications. They are widely used in various industries such as construction, agriculture, and marine. Each type of stainless chain has unique properties that make it suitable for specific tasks. For instance, some chains provide high strength while others offer corrosion resistance.

When considering stainless chains, it's crucial to understand their ratings and specifications. You might find chains ranging from light-duty to heavy-duty options. Some chains are designed for transport, while others are meant for lifting or securing heavy loads. Choosing the right type can be challenging.

In practical use, stainless chains require regular maintenance. Neglecting to lubricate or inspect them can lead to premature wear. It's easy to overlook these details, but doing so can be costly. Understanding the proper uses and limitations of each stainless chain can greatly enhance performance in any given application.

Stainless chains play a crucial role in various industries. In 2026, their significance is expected to grow even further. Key characteristics of top stainless chains include corrosion resistance, strength, and durability. According to a recent industry report, approximately 30% of chains will focus on improved anti-corrosion properties.

The choice of materials is essential. High-quality stainless steel offers better mechanical properties. Reports suggest that chains made from this material last up to three times longer than standard options. This longevity is vital in sectors like construction and manufacturing, where chain failures can lead to significant downtime and costs.

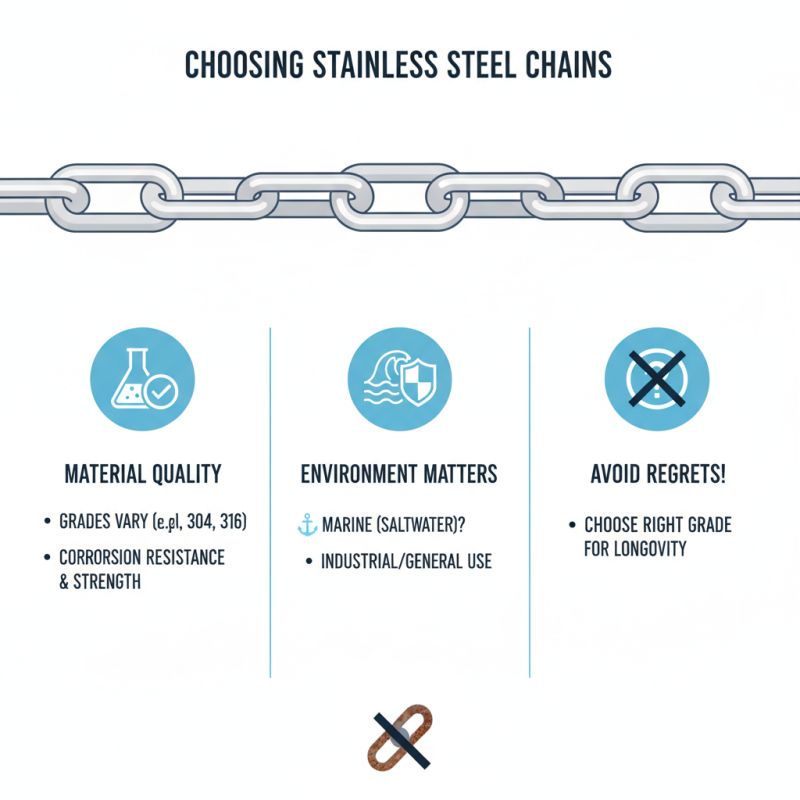

Size and grade also matter. Chains come in different grades, each suited for specific applications. For instance, grade 304 is commonly used for general purposes, while grade 316 has superior corrosion resistance, especially in marine environments. However, many suppliers still struggle to provide accurate specifications. This inconsistency raises concerns about performance and safety. It is crucial for buyers to validate information before making purchases.

When choosing stainless chains, there are several key factors to consider. The material quality is crucial. Stainless steel grades vary in corrosion resistance and strength. It is important to know the environment where the chains will be used. For example, marine environments may require higher resistance levels. Not all stainless chains are created equal. Some might rust after prolonged exposure to saltwater, leaving you with regrets.

Chain size and capacity matter too. The thickness of the links can affect the load-bearing ability. It’s essential to match the chain size with its intended use. An overly lightweight chain may fail under pressure. Conversely, selecting a heavier chain for a light application can be overkill. This imbalance can lead to unnecessary costs.

Finally, consider the chain's design. Some chains are more flexible and easier to work with. Others may offer more rigidity. Think about how the chains will be connected. Will they be attached to hooks or other equipment? The compatibility can impact performance significantly. Reflect on these factors carefully to make a better-informed decision.

When it comes to stainless chains, maintenance is crucial for longevity. Regular cleaning helps prevent rust and corrosion. Use warm soapy water and a soft brush to scrub away dirt and grime. Rinse thoroughly, then dry with a soft cloth. Remember, moisture is a stainless chain's worst enemy.

Tips: After cleaning, apply a light layer of lubricant. This creates a protective barrier against the elements. Be careful not to overdo it; too much can attract dirt. Inspect your chains regularly for signs of wear. Look for any fraying or discoloration. It's often a signal that something needs attention.

Stainless steel might not rust easily, but it still needs care. Storing chains in a dry place can extend their lifespan. Avoid leaving them in damp areas. Even the best materials need a little help to stay in top shape. Keeping an eye on your chains can prevent future issues. Sometimes, we overlook small details, leading to bigger problems later.

When comparing stainless chains to other materials, several factors come into play. Stainless steel chains are known for their durability and resistance to corrosion. In contrast, chains made from materials like plastic or coated metals may not offer the same level of strength or longevity. If exposed to harsh environments, plastic chains can degrade quickly.

Another concern is weight. Stainless chains are significantly heavier than their plastic counterparts. This heaviness can be a disadvantage in certain applications where weight reduction is critical. However, the added weight often equates to greater stability and strength.

Maintenance is another critical factor. Stainless chains require regular cleaning to prevent rust, especially in marine environments. Other materials, such as nylon, may be easier to maintain, but they lack the overall strength. Each material has its pros and cons, and choosing the right one depends on specific needs and conditions. Reflecting on these details can help clarify the material choice for any given project.

| Chain Type | Material | Strength (N) | Corrosion Resistance | Weight (kg/m) | Cost ($/m) |

|---|---|---|---|---|---|

| Stainless Steel Chain | Stainless Steel | 5000 | Excellent | 2.5 | 15 |

| Plastic Chain | Thermoplastic | 2000 | Good | 1.2 | 10 |

| Aluminum Chain | Aluminum Alloy | 3500 | Moderate | 1.8 | 12 |

| Carbon Steel Chain | Carbon Steel | 6000 | Fair | 3.0 | 8 |