In the world of industrial applications, the selection of the right stainless chain can significantly impact both operational efficiency and safety. According to a report by the Industrial Chain Association, approximately 30% of machinery downtime is attributed to the improper use of chains and related components. This statistic underscores the critical nature of choosing the appropriate stainless chain for specific applications.

As noted industry expert Dr. John H. Wells, a leading authority on material durability, states, "Investing in quality stainless chains not only enhances system reliability but also reduces long-term maintenance costs." This perspective is crucial for businesses seeking to optimize performance while managing expenses. Whether for lifting heavy loads, transport systems, or other demanding environments, the right stainless chain plays a pivotal role.

In this guide, we will explore the top five considerations when selecting a stainless chain tailored to your needs. By understanding the various grades, load capacities, and environmental factors, you can make an informed decision that supports your operations and aligns with industry best practices.

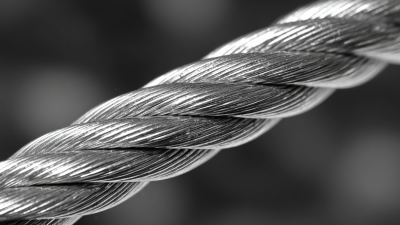

When selecting the best stainless chain for your applications, it's vital to consider various essential factors that directly impact durability and functionality. Firstly, assess the environment in which the chain will be used. For outdoor applications, chains with higher corrosion resistance, such as those made from 316 stainless steel, are preferable due to their superior ability to withstand harsh weather conditions and marine environments. In contrast, 304 stainless steel is suitable for less demanding indoor applications.

Tips: Always review the manufacturer's specifications regarding tensile strength and load ratings. This ensures the chain can handle the expected loads without risk of failure. It's crucial to factor in the weight of the items the chain will support to guarantee safety and efficiency.

Another critical consideration is the chain's size and pitch. Ensure that the dimensions align with the application requirements. Using a chain too large or too small can lead to improper functioning and increased wear.

Tips: To avoid common pitfalls, consult with experts or suppliers who can offer guidance based on your specific application needs. Gathering information and expert advice will not only save time but can enhance performance and longevity of the chain.

When it comes to selecting the ideal stainless chain for your specific needs, understanding the various types available can significantly simplify the decision-making process. Here are the top five types of stainless chains and their unique advantages.

First, we have the marine grade stainless chain, which is specially designed for saltwater environments. Its enhanced corrosion resistance makes it perfect for boating and other aquatic applications. Next, the hook chains provide easy attachment points and are commonly used in lifting and towing scenarios, making them incredibly versatile for various tasks. Meanwhile, roller chains are known for their efficiency in machinery, delivering reliable performance in power transmission.

Tips: When choosing a stainless chain, always consider the environment it will be exposed to—marine chains excel in saltwater, while others may be more suited for indoor use. Additionally, make sure to check the load capacity of the chain to avoid safety hazards. Lastly, look for chains that come with a warranty as a guarantee of quality and durability.

When selecting the best stainless chain for durability and strength, it’s essential to consider the applications where the chain will be utilized. The demand for stainless steel chains is on the rise, driven by their significant usage in various industries such as oil and gas, food processing, and automotive sectors. According to recent market reports, the growth of the stainless steel market is predicted to continue, reflecting a CAGR of 6.1% from 2024 to 2030, emphasizing the evolving needs in these applications.

In addition to understanding industry demands, it's crucial to evaluate the characteristics of different types of stainless steel. For instance, Austenitic stainless steel is known for its excellent corrosion resistance and overall durability, making it suitable for harsh environments. As manufacturers innovate and maintain stringent quality controls, choosing a high-quality stainless chain from a reliable source is vital for ensuring longevity and performance. With the German industrial chain sector leading the way in terms of technological advancements and product reliability, there are ample options for users looking to invest in durable stainless chains that meet their specific requirements.

The stainless chain industry is a fundamental component across various sectors, with four key industries particularly dependent on high-quality stainless chains: construction, marine, automotive, and jewelry. According to recent market research, the global stainless steel scrap market has shown significant growth, driven by increasing demand for durable and corrosion-resistant materials. The construction industry, in particular, has seen a surge in the utilization of stainless chains for scaffolding and safety applications, reflecting a broader trend towards enhanced safety standards and sustainable practices.

In the marine sector, stainless chains are valued for their resistance to saltwater corrosion, making them essential for anchoring and towing operations. A report indicates that the marine industry is pushing for higher quality standards, as the longevity of materials directly impacts operational costs. Similarly, the automotive industry relies on stainless chains for various components that require both strength and resilience, aligning with advancements in engineering and design. Finally, the jewelry sector continues to innovate with stainless chains, catering to trends in fashion while maintaining affordability and durability, highlighting the versatile nature of stainless steel across these vital industries.

Maintaining your stainless chain is essential for ensuring optimal performance and longevity. Regular inspections should be a part of your maintenance routine. Look for signs of wear, rust, or damage, as even minor issues can lead to more significant problems over time. Clean your chain regularly with a mild detergent and water to remove dirt and debris, which can cause friction and wear. It’s crucial to dry the chain thoroughly after cleaning to prevent moisture buildup.

Lubrication is another key aspect of maintaining your stainless chain. Use a quality lubricant designed for stainless steel to reduce friction and protect against corrosion. Apply the lubricant sparingly to avoid attracting dirt and grime, which can compromise the chain’s integrity. Remember to reapply lubricant after heavy use or exposure to harsh conditions. By investing time in proper maintenance, you can extend the life of your stainless chain and ensure it performs effectively when you need it most.

This chart represents the tensile strength of various stainless steel chains, which is a crucial factor in selecting the right chain for your needs. The different types of chains listed showed varying tensile strengths measured in pounds.