In the evolving landscape of 2025, the use of stainless steel shackles continues to be pivotal across various industries and applications. Renowned for their exceptional strength, durability, and resistance to corrosion, stainless steel shackles are increasingly recognized as indispensable components in lifting, rigging, and marine operations. Their robust construction ensures reliability in demanding environments, making them a preferred choice for professionals seeking safety and efficiency in heavy-duty tasks.

As industries adapt to the challenges and opportunities of the future, the versatility of stainless steel shackles proves beneficial for a multitude of purposes. Whether in construction, shipping, or recreational activities like boating, these shackles provide a secure connection point that enhances stability and performance. Furthermore, advancements in manufacturing technology are likely to lead to even more innovative designs, contributing to the shackle's performance in various applications.

The increasing awareness of sustainability and material efficiency also positions stainless steel shackles as a responsible choice for businesses aiming to minimize their environmental footprint. By investing in high-quality, long-lasting accessories, companies not only reduce waste but also ensure that their operations are built on a foundation of safety and resilience. In summary, as we look toward 2025, the strategic advantages of stainless steel shackles will undoubtedly play a crucial role in shaping modern industry standards and practices.

Stainless steel shackles are increasingly recognized for their versatility and durability across a range of industries in 2025. In marine applications, for instance, stainless steel shackles are essential for securing vessels and rigging equipment due to their exceptional corrosion resistance. According to a recent industry report, the marine sector is projected to utilize over 40% of the global shackle market by 2025, attributed to the ongoing growth in shipping and recreational boating. This durability allows for long-term use, reducing replacement costs and enhancing safety during operations.

In construction and heavy industry, stainless steel shackles are crucial for lifting and rigging applications. Their robust design and high tensile strength make them ideal for handling heavy loads, with reports indicating that stainless steel products can withstand loads exceeding 20 tons. The construction sector is witnessing a significant shift towards more sustainable materials, with stainless steel being a preferred choice due to its recyclability and longevity. As a result, it is projected that the demand for stainless steel shackles in construction will grow by approximately 25% annually, reflecting the industry's commitment to safety and sustainability.

Additionally, the burgeoning renewable energy sector, particularly wind energy, relies heavily on stainless steel shackles for turbine installation and maintenance. With the increasing number of offshore wind farms, the demand for secure and reliable rigging solutions has surged. Analysts predict that the use of stainless steel shackles in this sector will double by 2025, underscoring their vital role in ensuring the operational efficiency and safety of renewable energy projects.

Stainless steel shackles play a crucial role in marine applications, providing strength and durability essential for various maritime activities. Their corrosion resistance makes them particularly well-suited for environments exposed to saltwater, humidity, and extreme weather conditions. Unlike their mild steel counterparts, stainless steel shackles maintain structural integrity over time, ensuring reliable performance whether used in boating, fishing, or industrial maritime operations. This reliability reduces the risk of equipment failure during critical tasks, making them a preferred choice among marine professionals.

Moreover, the versatility of stainless steel shackles extends to their multiple designs and load ratings, catering to a wide range of anchoring, towing, and rigging needs. Their robust construction allows for safe connections in high-load scenarios, which is essential for tasks such as securing loads on vessels or connecting elements in mooring systems.

Additionally, the aesthetic appeal of stainless steel can also enhance the overall look of marine equipment, combining functionality with visual appeal. As the demand for durable and efficient solutions in the marine industry continues to grow, the importance of stainless steel shackles will only increase.

Stainless steel shackles have gained prominence in various industries, particularly in construction, marine, and rigging applications, due to their superior safety and durability. According to a report from the International Association of Lifting and Moving Equipment (IALA), the use of stainless steel in shackles can enhance load-bearing capabilities by up to 20% compared to traditional materials. This increase in strength not only provides additional safety but also reduces the likelihood of failure under extreme conditions, making stainless steel shackles the preferred choice for critical lifting operations.

Moreover, stainless steel's resistance to corrosion significantly enhances safety, especially in marine and industrial environments where exposure to elements is a constant threat. A study by the National Association of Corrosion Engineers (NACE) indicates that stainless steel shackles can last up to five times longer in corrosive environments compared to their galvanized counterparts. This longevity not only translates to fewer equipment failures but also decreases maintenance costs and downtime, further emphasizing the importance of choosing stainless steel for safety-conscious applications. The growing adoption of stainless steel shackles in 2025 aligns with a broader industry trend towards more robust, reliable equipment that prioritizes safety in every operation.

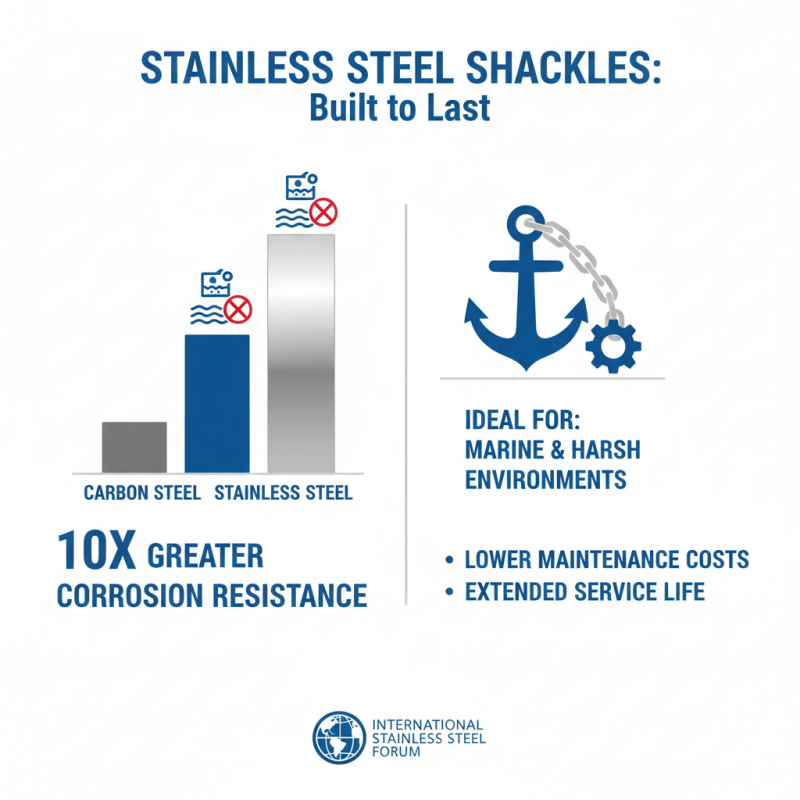

When it comes to selecting shackles for various applications, the choice of material can significantly influence performance and longevity. Stainless steel shackles have gained prominence due to their superior corrosion resistance and structural strength. According to a report by the International Stainless Steel Forum, stainless steel can exhibit up to 10 times greater resistance to corrosion compared to traditional carbon steel, making it ideal for marine environments and industries subject to harsh conditions. This durability directly translates into lower maintenance costs and extended service life, a crucial factor for operations relying on equipment performance.

In contrast, while aluminum shackles offer lightweight advantages, they tend to lack the strength and durability of stainless steel under heavy loads and extreme conditions. A comparative analysis published in the Engineering Materials Journal indicates that stainless steel shackles can handle significantly higher tensile loads—reporting up to 20% more strength than their aluminum counterparts. Furthermore, when assessed for safety factors, the reliability of stainless steel shackles in critical applications is underscored by their ability to withstand operational stresses without deformation or failure, which is essential in construction, lifting, and safety-critical operations. This makes stainless steel an unequivocal choice in scenarios where safety and performance are paramount.

The manufacturing of stainless steel shackles is expected to evolve significantly by 2025, driven by advances in technology and a growing emphasis on sustainability. One notable trend is the integration of automation in the production process, which enhances precision and efficiency. Advanced robotics and computer-aided design are increasingly used to streamline manufacturing, resulting in more consistent quality and reduced waste. This shift not only lowers production costs but also minimizes the environmental impact of shackle manufacturing, aligning with global demands for eco-friendly practices.

Additionally, innovation in material science is leading to the development of new stainless steel alloys that offer improved strength and corrosion resistance. These advancements will cater to demanding applications in industries such as construction, marine, and heavy lifting, where reliability is paramount. The rise of smart technologies, which can monitor the condition and performance of shackles in real-time, is also anticipated. This will enhance safety and efficiency in various applications, allowing users to make data-driven decisions and extend the lifecycle of their equipment. As the industry moves forward, the focus will remain on creating high-performance products that meet the evolving needs of users while supporting sustainable practices.

| Application | Key Benefits | Future Trends |

|---|---|---|

| Maritime Industry | Corrosion resistance, strength, and durability | Increased use of specialized coatings for enhanced durability |

| Construction | High load capacity and reliability | Integration of smart technologies for monitoring stress and load |

| Aerospace | Lightweight yet robust, reducing overall aircraft weight | Advanced manufacturing techniques using 3D printing |

| Oil and Gas | Resistance to harsh environments and stress | Development of high-strength alloys for extreme conditions |

| Marine Equipment | Safety and functionality in marine applications | Expansion of eco-friendly materials in manufacturing |